Oshima Taiwan, established in 1971, pioneered the nation’s garment industry. Starting with the most basic bonding equipment, it researched and developed other necessary equipment and machinery as required. Taking note of the digital trend in the industry, the company has also designed “digital upgrades” to keep up with the times.

According to Oshima Department of Domestic Sales Manager Mike Lin (林昆融), Oshima Taiwan is the only manufacturer, globally, that can provide the gamut of services from front-end inspections to back-end system integration.”

Increased sophistication of technology has raised manufacturers’ expectations regarding standards for original equipment manufacturers (OEM) and original design manufacturers (ODM), demanding greater security mechanisms, higher production efficiency and greater quality.

These demands, coinciding with a labor shortage and loss of experience as the older generation retires, make it difficult for new hires to maintain high-quality products.

Like other labor-intensive traditional industries, the textile industry is suffering from labor shortage as more and more countries experience their population structure shifting to hyper-aged societies. While the initial response has been to relocate manufacturing plants to low labor overhead countries in Southeast Asia or Africa, the growing logistics of which balanced the reduced labor costs. In addition, unexpected international events and natural and human-caused disasters often compound manufacturing costs and create more pressure on manufacturers regarding disaster prevention.

Oshima has also noted that some of the more renowned foreign brands are only investing in particular types of equipment, or only parts of the supply chain, presenting a difficulty in machine integration for manufacturers and diminishing inclination to throw money into machinery that serves only to increase cost, rather than decrease.

Oshima recognizes that the clothing industry is embracing automated production, and it has ensured that its machinery is tuned to the most advanced and modern specifications and uses state-of-the-art human-machine interfaces. In addition, Oshima’s upgraded machinery all share a collaborative wireless network that allows for a lower-cost transition to fully automated production.

|

|

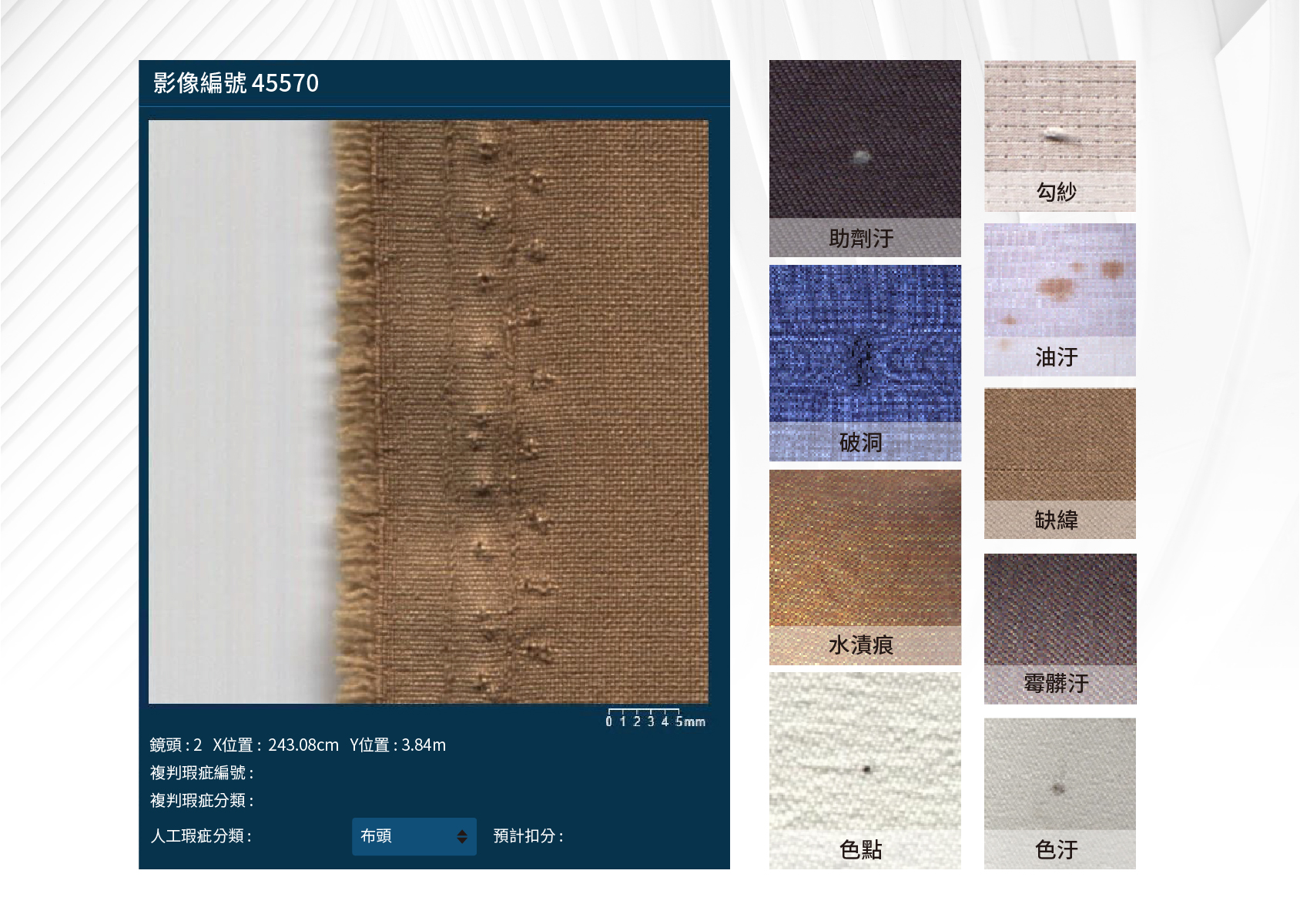

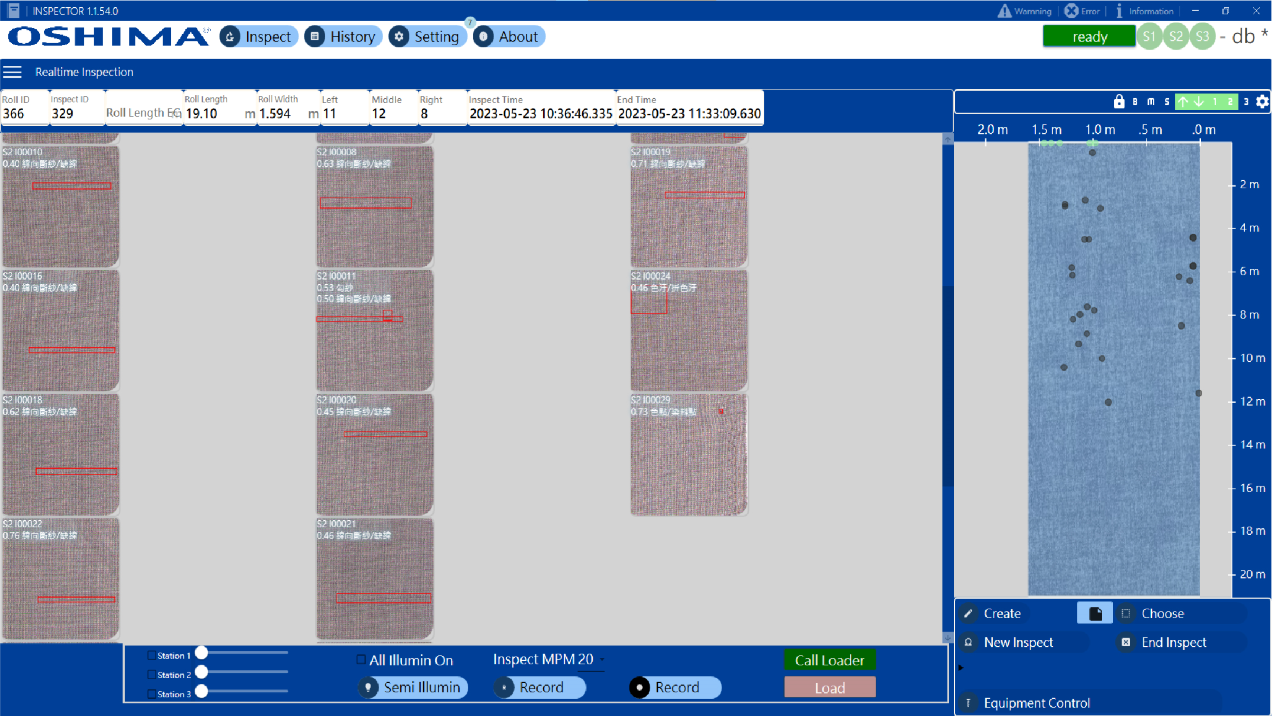

| Achieve sharper insights with our 8K UHD camera and 360-degree lighting, ensuring accurate inspection results. | Defect model (Fabric defect type) |

Production automation fulfills the essential requirement for manufacturers of excellence, which is to establish standards that ensure excellence in quality, efficiency, and production rate of its products. Furthermore, “smart” production lines impact manufacturers less if needed to be relocated to countries with a lower average education.

Oshimia has recognized that establishing standard operating procedures (SOP) could expedite personnel training, presenting an opportunity to increase one’s production ratio at a high-tech but low-learning threshold job.

Workers would only need to input pre-set parameters or assign tasks through the computer system for work to be done. It would minimize human errors during production processes and contribute to stable quality. In addition, two people can handle the workload requiring 6-8 people in the past, yielding significant profit margins.

Compared with non-automated systems, Oshima’s products and specifications are undoubtedly more expensive. Still, what it asks for in price is more than compensated for by reducing labor costs, increasing efficiency and broadening profit margins.

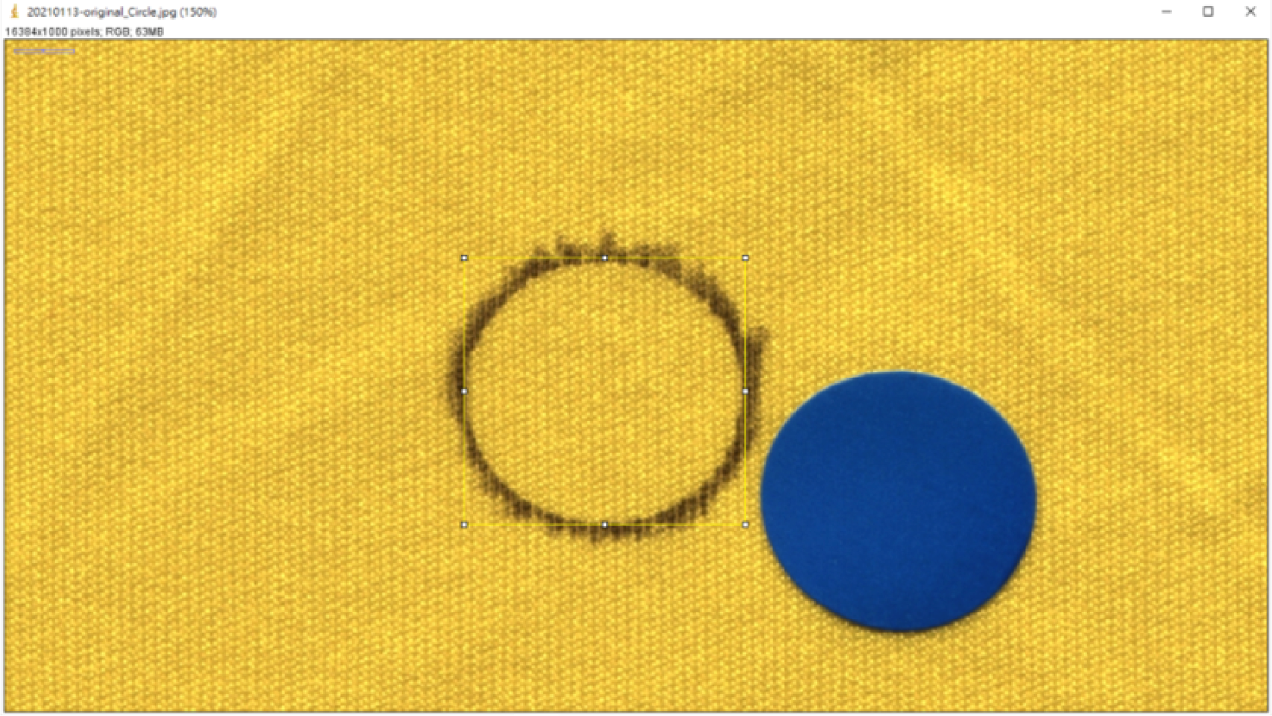

Recognizing that lacking methods to automate quality checks would greatly diminish the value of automated factory lines for the industry and learning from previous experiences of using automatic Optical Inspection (AOI) equipment that such methods would only work with plain-colored garments made from inflexible cloth, Oshima worked with other Taiwan-based textile industry owners, alongside academic experts, to explore the possibility of developing an AI program to conduct cloth checking.

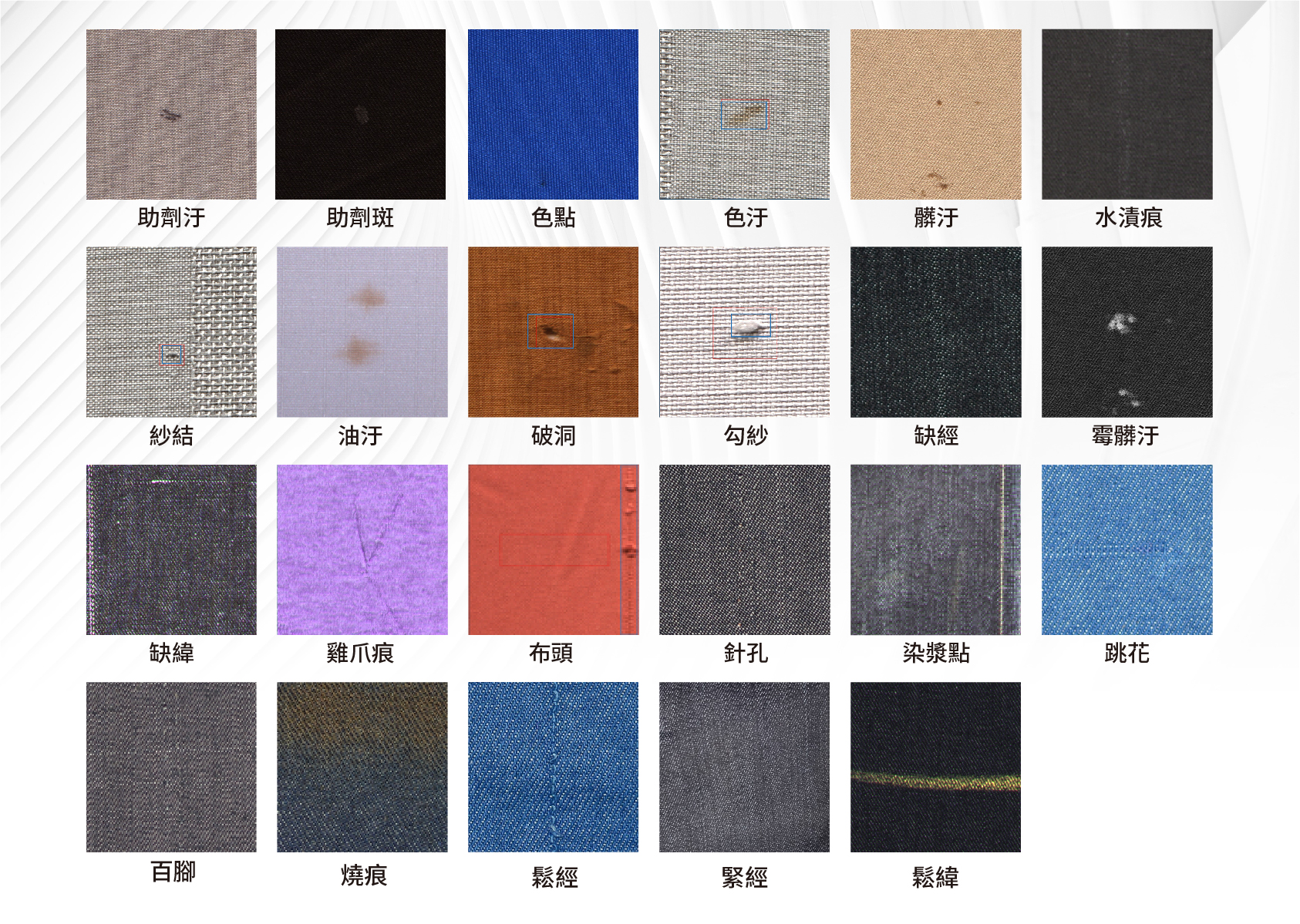

The goal was to develop a system that could inspect more varied types of cloths, regardless of make, knitted or woven, style, patterned or plain, or color, single colors vs. multi colors, and generate a report based on the US four-point system, thus helping industry owners understand the quality of the cloth per the industry’s standards.

|

|

| Experience seamless inspection of elastic fabrics with our machine, featuring a tension guarantee of ≤2_. | Process fabrics quickly with 0.7s frame image processing and 0.5s frame for image re-checking. |

According to Oshima’s Marketing department specialist Bonnie Teng (鄧詠心), Oshima’s equipment is more efficient and accurate than others, especially when inspecting flexible cloth products, broadening the range of cloth materials Oshima machinery could examine.

US clients in OEM and ODM sports manufacturing using Oshima equipment said that the machines were comparatively easier to integrate into a manufacturing line compared to other brands and could accommodate more cloth material types, as well as proving to be more accurate in all things.

Oshima’s in-house R&D and information technology (IT) specialists allow it to make detailed plans and adjustments customized to meet client needs, providing excellent service for its clients.

During the COVID-19 pandemic that took the world by storm, Oshima had tasked its R&D and IT teams to work with clients to manufacture machines that can simultaneously spread nine layers of non-woven cloth, granting its clients the capability to expedite the manufacturing of masks and protective clothing, both products which were essential and have helped save many lives during the pandemic.