The growing prevalence of 5G networks and electric-powered cars results in increased use of wide-bandgap (WBG) materials, such as silicon carbide and gallium nitride, in third-generation semiconductors as they are critical in overcoming high-voltage-induced heating issues.

However, processing hard materials into extremely thin wafers requires great precision and high operational stability, both demands which are met by hydrostatic bearings.

The advantage of hydrostatic bearings is that no matter at zero speed (stationary state), starting, or rotating, the rotating part (mandrel) remains suspended in the middle, , and its non-contact and frictionless characteristics serve to enhance product durability.

Hydrostatic bearings are used as the main spindles or guide rails for processing machines as they possess low friction, high rigidity and long service life. In addition, the bearing’s shock-resistance capabilities could provide next-generation wafer manufacturers with a more stable means to process silicon carbide.

During the early days of Grintimate’s establishment in 2015, it went out of its way to hire a technical supervisor with more than 10 years of experience in the hydrostatic technology field to join the team. Said supervisor helped re-plan and re-design the oil circuits and hydrostatic spindle cooling system to mitigate the effects of thermal deformation on the bearings effectively.

The system has since been applied to other components, such as the rotary worktable and slide rails.

Grintimate also developed a high-speed direct-drive hydrostatic bearing spindle, which could reach maximum linear speeds of up to 120m/s, in 2021 and resulted in the company’s obtaining a new patent, No. M620627.

On top of the extreme pressures available to hydraulic-powered machinery, the high rigidity of the grinder can handle heavy cutting while maintaining stable and high precision - to within 2μm - during the machining process.

These characteristics make it an ideal machine to process WBG materials, which are increasingly used when manufacturing third-generation semiconductors, SiC, GaN, wafers, or ceramic vacuum chucks.

Grintimate’s Horizontal Hydrostatic Rotary Surface Grinder (GRC-series) utilizes the company’s signature hydrostatic spindle alongside a rotary table - whose rigidity exceeds 400 kilogram-force per microgram and has a diameter of 600 - that can sustain 10,000kg of load.

|

|

| Grintimate GRC-060 | Ceramic Vacuum Chuck |

The grinder’s rotary table differs from the traditional reciprocating grinding method, reducing movement during processing and allowing special grinding procedures, such as making it convex or concave or multi-stage grinding for a round or ring-shaped workpiece.

The difficulty in grinding and polishing of silicon carbide is challenging due to its hardness, making it an easily monopolized product as only some manufacturers can produce the requisite machinery.

The semiconductor industry supply chain is fragile and intricate, and any single point of failure could cause a cascade effect down the supply chain, a vulnerability Grintimate seeks to shore up by introducing high-stability, long-serving hydrostatic bearings.

Grintimate’s vertical hydrostatic wafer grinder (GTR-1215), the only one of its kind in Taiwan, hopes to strengthen the country’s capabilities for manufacturing third-generation semiconductors and establish Grintimate’s name in the industry by significantly increasing the grinding yield rate and the optimized production process by introducing innovative cooling system and chip removal design.

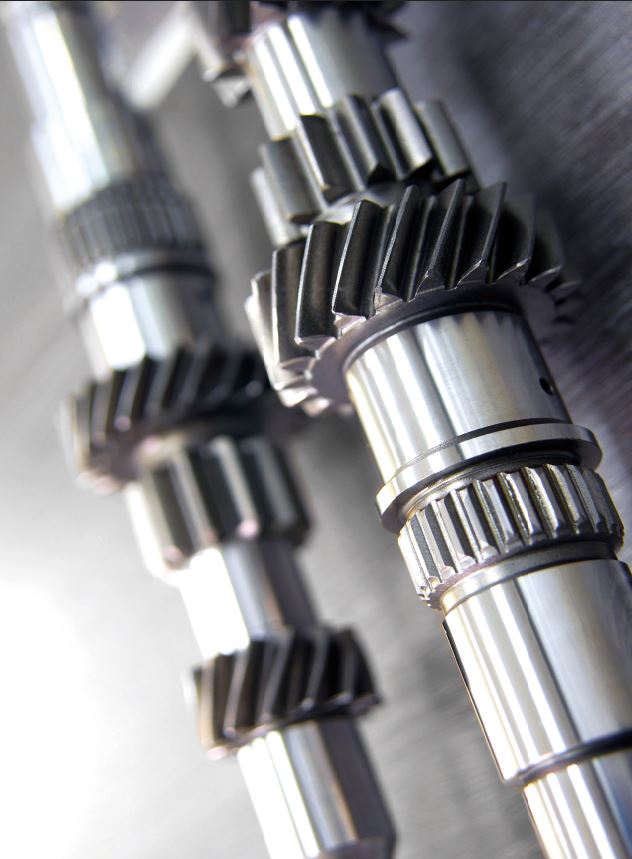

The Hydrostatic Cylindrical Grinder Specialized for Transmission Shaft (CTS-100), comes equipped with a hydrostatic spindle and an X-axis hydrostatic guideway. The grinding wheel can be widened to a maximum of 300mm with one-feeding grinding (max. 15-steps), which can satisfy the customer’s required processing accuracy.

|

|

| Grintimate CTS-100 | Grinding Wheel Dressing |

Only one-time processing with the formed grinding wheel is needed to achieve the requisite dimension accuracy, quality and processing efficiency. In addition, the headstock and tailstock work with double-sided synchronicity, preventing interference between carrier and workpiece during the grinding process and significantly improving production efficiency.

Grintimate said, “we have a customer brough the German-manufactured roll grinders, the machine is also equipped with hydrostatic bearing spindle. Every time while the machine is shutdown, they have to ship the spindle back to Germany for analysis and repairs, making it an expensive and long waiting time.

Grintimate said all its hydrostatic spindles are designed and manufactured at its plant, ensuring the quality of its products and the perfect assembly of all parts and components.

With an ample supply of spare materials, Grintimate said its hydrostatic spindle technology is mature and of comparable quality to that of Japan and Germany.

Grintimate is confident that, as one of the top global brands manufacturing hydrostatic spindles, it can provide the best and most complete solution for its clients, regardless of technological maturation, professionalism, or the speed of after-sales service.

|

|

| Grintimate CAC-055 | Gear Shafts |

About Grintimate

https://www.grintimate.com/