Most ferrous alloys can be welded, such as carbon steel, low alloy steel, aluminum alloy, stainless steel and nickel alloys. Two materials do not necessarily need to be of the same material; dissimilar metals such as aluminum to steel can also be flash butt welded.

Application-wise, ferrous metal bars such as flat bars, rectangular bars, H-section, round bars and rebars. Cylindrical-shaped items include engine rings, gasket rings, hoist rings, motorcycle rims, automobile rims, scooter rims, bicycle rims, flanges, etc. Railway welding is also another typical flash butt welding application.

Dahching has developed customized flash butt welding machines to join steel and aluminum motorcycle rims, steel scooter rims, automobile rims, aluminum bicycle rims, gaskets, rings for car use, chair frames, flat bars, rebars, aluminum profiles, etc.

Dahching also has successfully joined dissimilar materials. Welding aluminum sheets to steel bus bar is a good example. Aluminum has a low melting point of around 700o while steel bus bar melts at a much higher temperature. Joining of the two materials requires precise control in welding voltage, welding current and the weld force.

Flash Butt Welding machines in three phase DC inverter power conversion or so called “Medium Frequency Direct Current Flash Butt Welding” machines are a perfect solution for energy saving. Balanced three phase input, minimal primary power consumption and rigid weld strength are the merits for selecting a “Three Phase DC Inverter Flash Butt Welding”.

Dahching also provides deburring machines which are tailor-made to remove excess weld burs. As the deburring machine is designed around the shape of the weldment, it is mainly tailor-made upon customer requests.

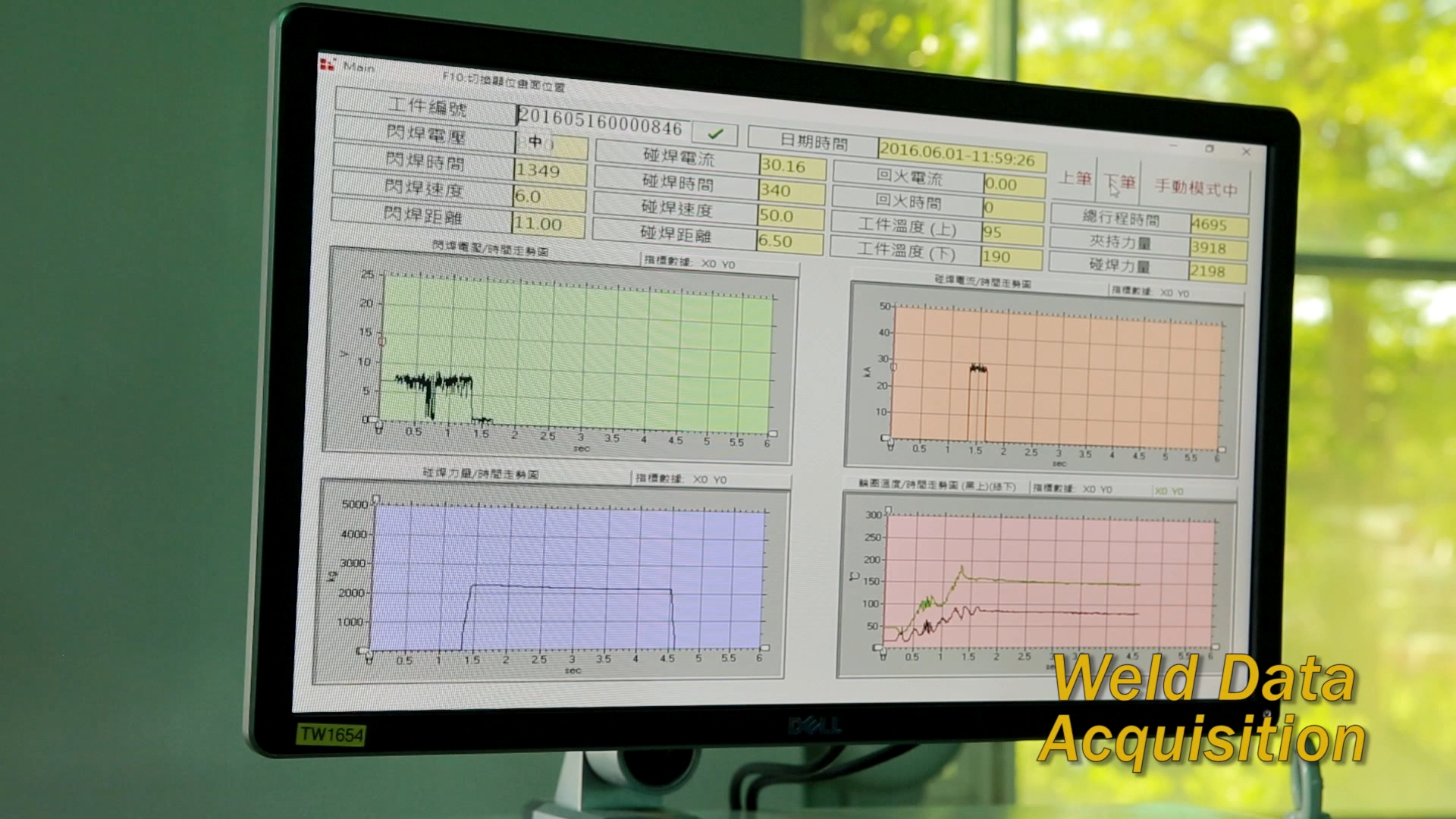

Weld data, production data acquisition, and predictive maintenance functions are also available upon customer request. Laser mark a QR code or bar code which contains the production data on the welded part is an Industrial 4.0 solution Dahching hopes to bring to customers.

About Dahching Electric Industrial Co., Ltd.

Established in 1979, Dahching Electric Industrial Co., Ltd. is an experienced welding machine manufacturer specializing in customized production of resistance welding machines for custom applications such as: Spot Welding, Projection Welding, Seam Welding, Flash Butt / Butt Welding and Heating / Upsetting applications intertwined with single phase or three phase DC inverters, DC capacitor discharge, and three phase rectified DC current solutions with distinct welding penetration.

https://www.dahching.com/