Furthermore, the center position and radial profile of a shaft can be automatically detected using TIMI's patented technology by rotating the shaft once without precisely centering the shaft. This technology has been widely used for rotational shaft geometry measurement.

TIMI image measuring machines are more commonly used in on-site in-process inspections, in addition to routine first-article inspection and in-process sampling in the QA laboratory. TIMI image measuring machines have high-precision, high-speed, and multi-functional inspection performance, as well as system design suitable for on-site inspection, and can also pre-establish measurement scripts for automatic full-dimension measurement. WIn general, TIMI can automatically measure a shaft with 20 inspection dimensions in about 20 seconds on average, allowing it to meet full inspection requirements.

All TIMI image measuring machines include a measurement database, and any data generated by TIMI is automatically saved and an inspection report is generated. Users can browse and screen these inspection data, but also conduct process statistics and process capability analysis. Furthermore, the real-time X bar and R chart are reliable sources of information for in-process quality control. Any ERP/MES system can be linked to the TIMI measurement database. All product inspection data, including product code, process code, and control upper and lower limits, can be directly imported into the TIMI measurement system from the ERP/MES system.

Following the inspection, the TIMI measurement database will record the production data, including the inspection date, inspector, machine code, and inspection data, and send it back to the ERP/MES system. This gives the manufacturer a very complete production history of any product.

The TIMI image measuring machine has been successfully integrated with the turning/grinding machine and the robotic arm for Industry 4.0. The machined shaft is transported from the machine tool to the measuring machine via the robotic arm for automatic full-dimension inspection. The unqualified size is fed back for correcting the machining parameters, and the measurement data is automatically saved and uploaded to the ERP system. It results in an intelligent shaft manufacturing system.

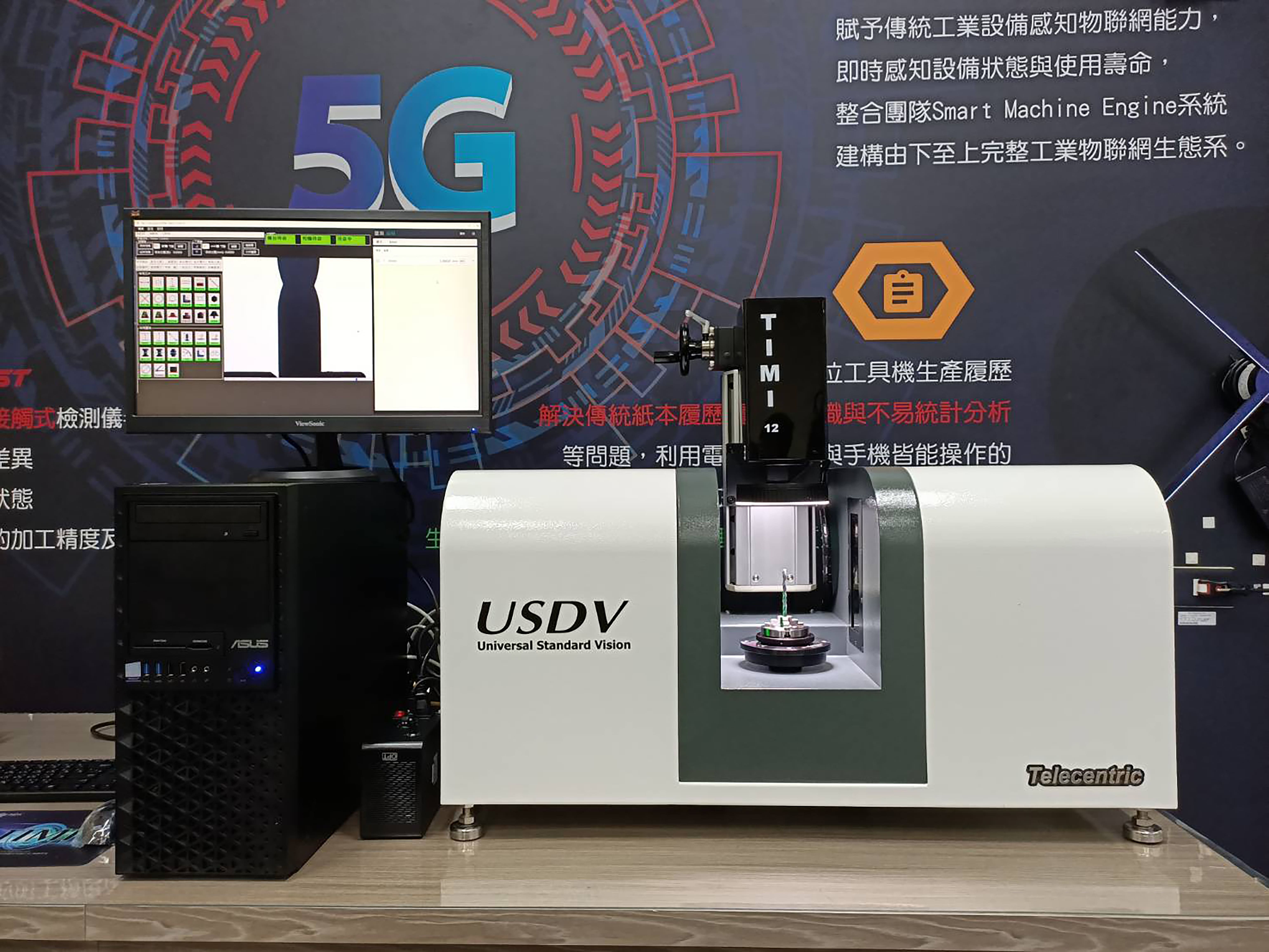

USDV ~ A Professional Team in In-line Intelligence Measurement

Universal Standard Vision Tech Corp. (USDV), is Taiwan's first leading company with R&D capability to develop high-precision telecentric image automatic measurement system. Its core teams are from a national-level R&D institute, the Industrial Technology Research Institute (www.itri.org.tw). USDV has extensive experience in the development of precision measurement software and hardware.

USDV develops automatic measurement systems for workpieces measurement in the aerospace, automobile, locomotive, bicycle, electrical and electronics, information and communications, medical equipment, power tools, turning/grinding, fasteners, and metal processing industries. Its measurement systems solve the problems of insufficient automatic measurement, difficulty with master dimension measurement, high inspection costs of manual measurement, and full inspection. Our telecentric image automatic measurement/inspection series equipment is suitable for first article inspection, incoming inspection, production line inspection and final product dimensional measurement. Many well-known vehicle component suppliers in Taiwan, China, India, and Vietnam have approved our series measurement machines.

In response to the severe labor shortage and the difficulty in training qualified inspectors, USDV newly developed in-line intelligent automatic measurement system for Industry 4.0. It’s equipped with a network database and can be used in conjunction with robot arm assisted solutions. The system realizes the benefits of intelligent measurement on the production line. This system has been installed at the manufacturing site of a well-known transmission shaft manufacturer in Taiwan.

Company: Universal Standard Vision Technology Corp.

https://www.usdvision.com/

MaryAnne Wei | maryanne@usdvision.com