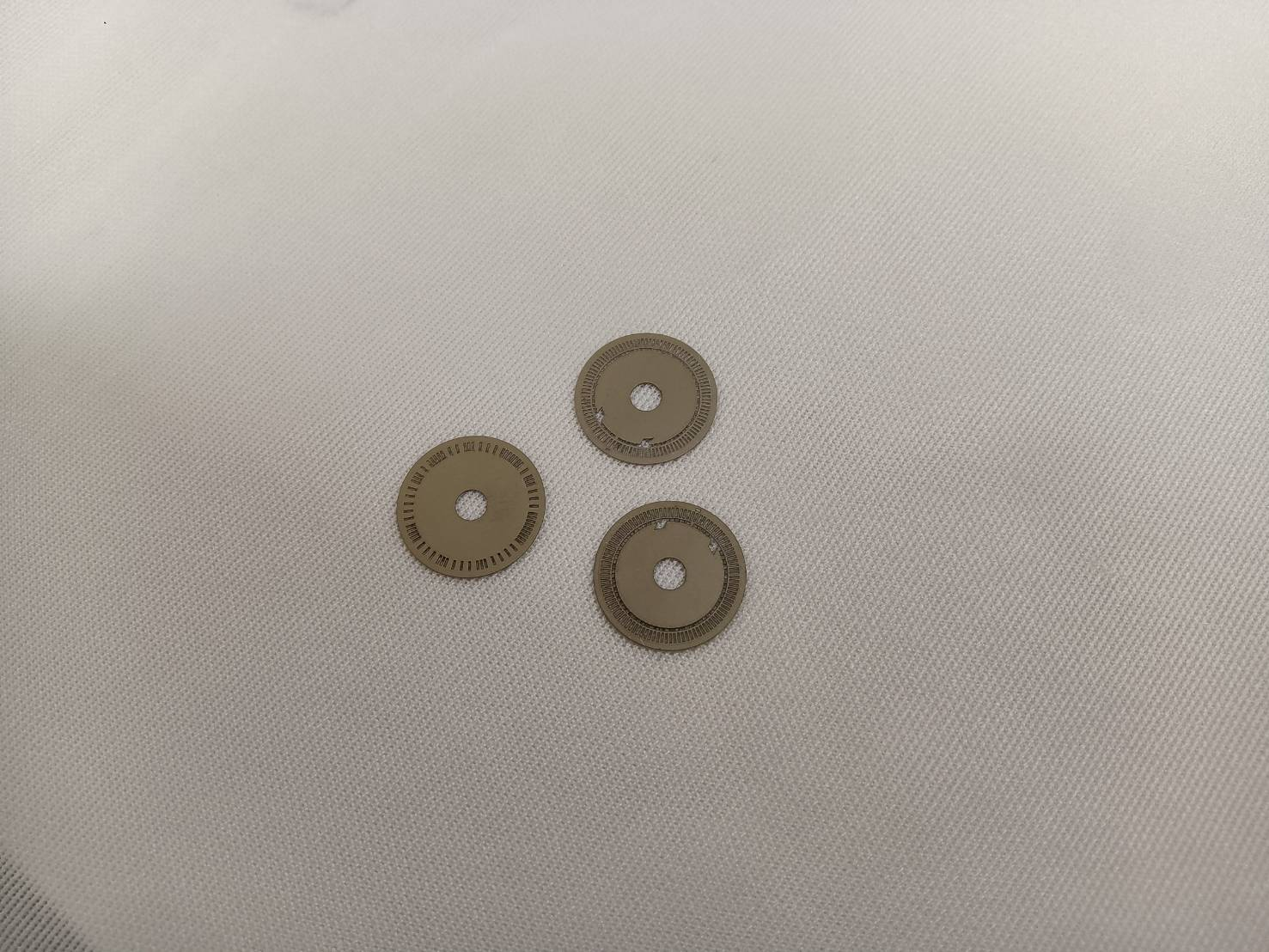

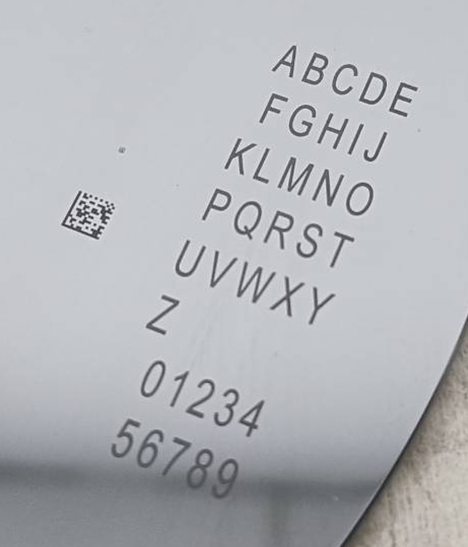

Many technological products, including machine tools, electrical vehicles, medical tools, and electronics, rely on micro, mini sensors and control components to perform intelligent functions. Different types of scales for optical encoders in machine tools, including linear, drum, and disc scales, serve as examples. Another example can be found in the periscope lens installed in the latest smartphones. The laser machines that Hortech develops can perform precision processing to produce these miniaturized sensors and high-precision control parts.

Three core patented techniques, including laser micro-etching, micro-drilling, and micro-cutting

Hortech is the only company that is capable of self-developing precision laser machines in Taiwan. The machines it develops can perform laser micro-etching, micro-drilling, and micro-cutting, which are required by a wide variety of technological and medical applications. It also plans processes and calibrates parameters, including micro-drilling and micro-cutting processes required by the third generation of silicon wafers, and micro-etching processes required by fabricating precision scales for optical encoders.

|

|

Dry laser etching - the most eco-friendly etching solution

Hortech employs dry laser etching, which is in contrast to the wet etching techniques that the semiconductor industry frequently employs. This can achieve the precision at +/- 0.5 μm or even lower. It does not produce chemical pollutants and waste, which reduces the negative effects to the environment. It is an eco-friendly etching solution.

Recently, Hortech launched the deep ultraviolet laser machine with large power that can perform cold laser processing and surface treatment. It is a solid laser that is characterized by short pulses. It does not produce thermal effects when performing precision laser processing on diverse materials.

In addition, Hortech collaborates with a Swiss manufacturer to develop waterjet laser machines that can cut materials harder than HRC60, including SiC and diamond blades. These can be installed on either vertical or horizontal turning centers (or conventional lathe and milling machines). Furthermore, these machines can save energy and be economically effective.

In addition to developing precision laser machines, Hortech provides laser processing and surface finishing services. Such services have been requested by diverse industries, including industrial automation, robotics, semiconductor 3D packaging, key parts of precision machine tools, chips of biomedical sensors, electrical vehicles, advanced display, and autonomous vehicles.

|

|

Specialize in optical laser, machining, and electrical engineering

System integration optimization

Hortech’s founder Dr. Owen Li holds degrees awarded by National Taiwan University, National Taiwan University of Science and Technology, and National Chiao Tung University. His expertise lies in optical laser, machining, and electrical engineering. He has devoted himself to developing laser technologies for more than 30 years. Hence, Hortech can integrate different parts and components from a holistic perspective. It comes up with the best solution based on characteristics of different parts when developing laser machines that meet sophisticated industrial needs.

You may find Hortech in international exhibitions. Hortech custom designs machines that can perform mass production according to clients’ specific needs. The yields of the laser machines that Hortech designs range from 95% to 98%, which significantly enhances international clients’ production.

Hortech will continue developing innovative laser technologies. In addition to improving the cold laser process and satisfying clients’ demands for high precision, it will design laser machines that reduce carbon emissions and safeguard the operation safety in demanding workplaces.

About Hortech