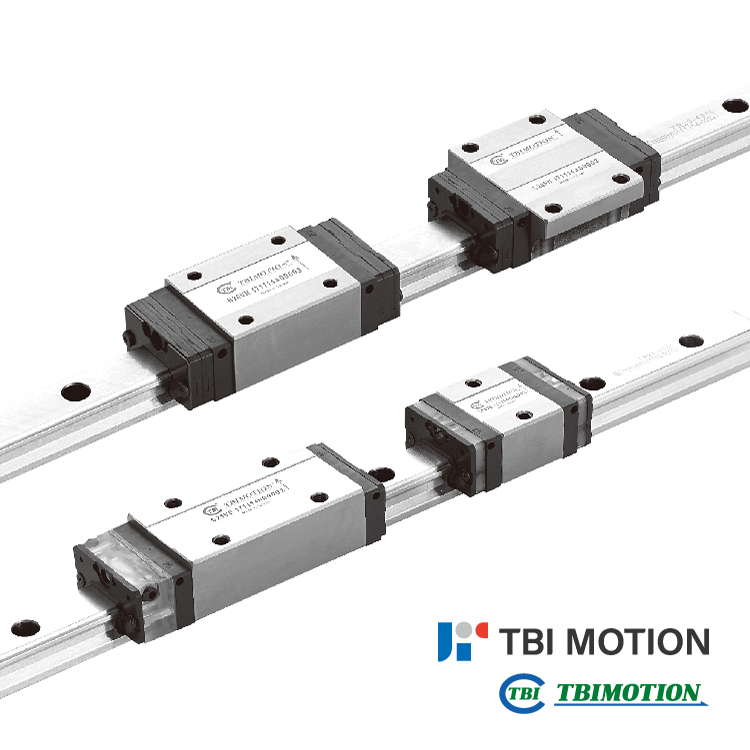

TR Series / TM Series

TBI MOTION TECHNOLOGY CO., LTD.

Compared with high-skill required scrapping process of traditional slide system, the Linear Guide can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of Linear Guide gives a convenience for installation and future maintenance.

●High Accuracy

Because linear guide has little friction resistance, only a small driving force is needed to move the load. Low frictional resistance helps the temperature rising effect be small. Thus, the frictional resistance is decreased and the accuracy could be maintained for long period than traditional slide system.

●High Rigidity

The design of Linear Guide rail and block features an equal lead rating in all four directions that request sufficient rigidity load in all directions, and self-aligning capability to absorb installation-error. Moreover, a sufficient preload can be achieved to increase rigidity and makes it suitable for any kind of installation.

●Easy for Maintenance

Compared with high-skill required scrapping process of traditional slide system, the Linear Guide can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of Linear Guide gives a convenience for installation and future maintenance.

●High Speed

Linear Guide block, rail and ball apply by contact point of Rolling system. Due to the characteristic of low frictional resistance, the required driving force is much lower than that in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation.

●High Performance without Clearance

Even under a preload or regular load, the ball and raceway contact one another at two points in the loading direction, as shown. This design gives rise to a smooth rolling motion.