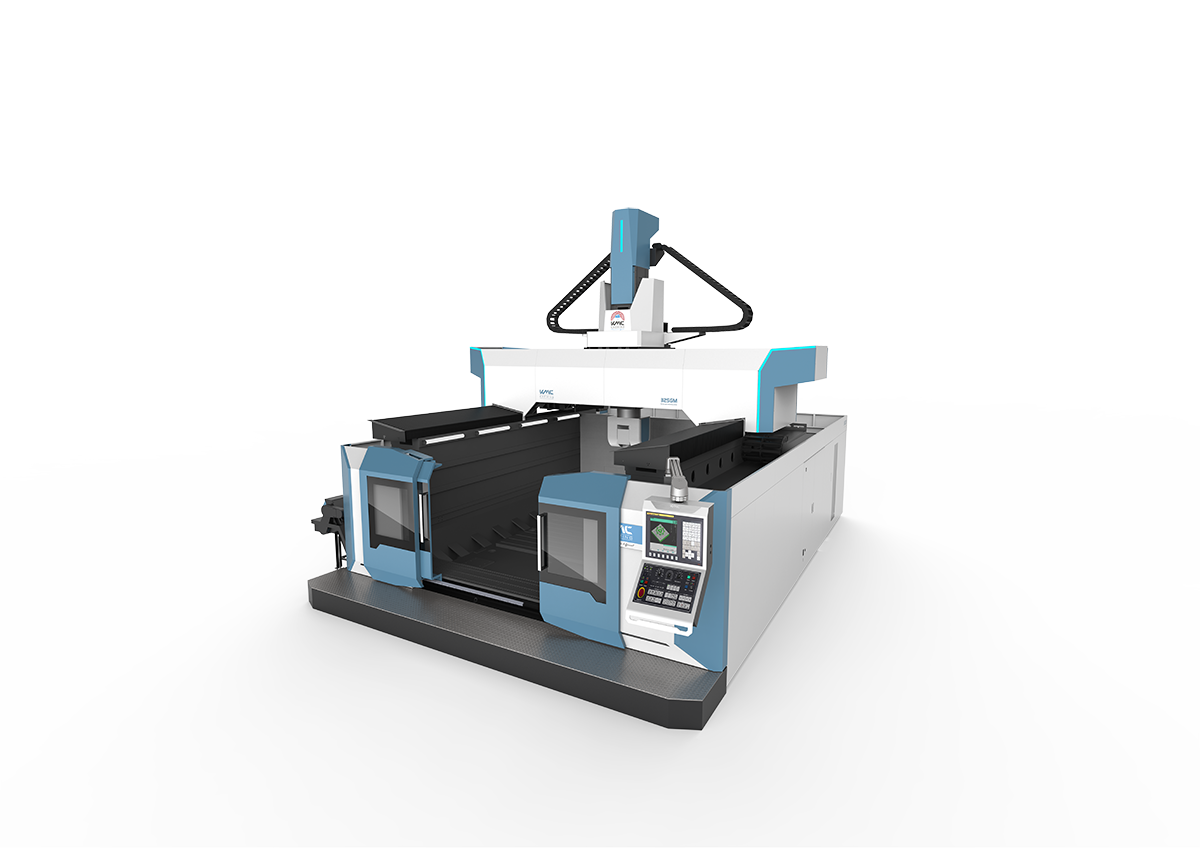

KMC-GM series (Gantry Mercury)

KAO MING MACHINERY INDUSTRIAL CO., LTD.

Intelligent Five-Axis Gantry Type Machining Center- KM-325GM model is superior to similar models in the market due to multiple outstanding design features and a combination of the best performance qualities. The machine is equipped with a high-speed build-in spindle - 24000 rpm and merely no limited loading capacities (3 ton/m²).

Intelligent Five-Axis Gantry Type Machining Center- KM-325GM model is superior to similar models in the market due to multiple outstanding design features and a combination of the best performance qualities. The machine is equipped with a high-speed build-in spindle - 24000 rpm and merely no limited loading capacities (3 ton/m²).

Unique box-in-box design achieves thermal symmetry and ends the thermal elongation deformation problem, therefore increasing the overall accuracy of the machine by 30% and improving the processing accuracy by 25% and, equipped with 2 motors with 2 ballscrews allow the machine to achieve maximum structural stability, avoid any overhang problem, and guarantee the best rigidity. HSK motor spindle with 2 Axis swiveling head highest surface quality simultaneous universal application. 10-20% faster machining time due to linear guideway, single-piece cast iron machine bed let the machine more stable and rigid, and the water leakage problem of the sheet metal joint is solved

Besides, its elaborated 3 axis coolant system, which includes inner cooled ballscrews, coolant system in bearing seat, and cooling circuit of the motor board guarantees the highest long-term accuracy and temperature stability. All axis adopt a linear scale system to ensure precision.

Solving the problem from the machine design fundamentally is the name of game.