S / Y / A / H / I / V / U / K / M / YA / NI / NU / NH / SCI / BSH / XSV

TBI MOTION TECHNOLOGY CO., LTD.

The high efficiency of ball screws is vastly superior to conventional screws. The torque required is less than 30%. Linear motion can be easily changed from rotary motion.

●Smooth Operation

The high efficiency of ball screws is vastly superior to conventional screws. The torque required is less than 30%. Linear motion can be easily changed from rotary motion.

●High Rigidity and Preload

When axial play is minimized in conventional screw-nut assemblies, the actuating torque becomes excessive and the operation is not smooth. The axial play in TBI MOTION precision ball screws may be reduced to zero by preloading and a light smooth operation is still possible. therefore, both low torque and high rigidity can be obtained simultaneously.TBI MOTION ball screws have gothic arch groove profiles which allow these conditions to be achieved.

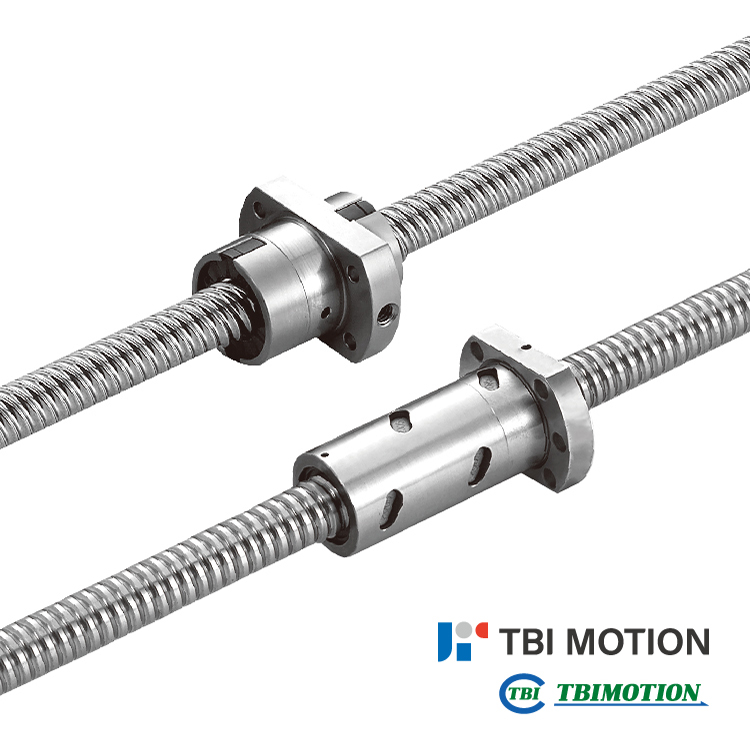

●Circulation Method

Ball return tube method. (V, A, H, Y Type); Ball deflector method. (NI, NU, M, K Type)

●High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience, have resulted in the most durable ball screws manufactured.

●Application

Automation industry, Semi-conductor industry, Industrial machine, Medical industry, Green energy industry, Machine tool, Automated storage and retrieval system and etc.