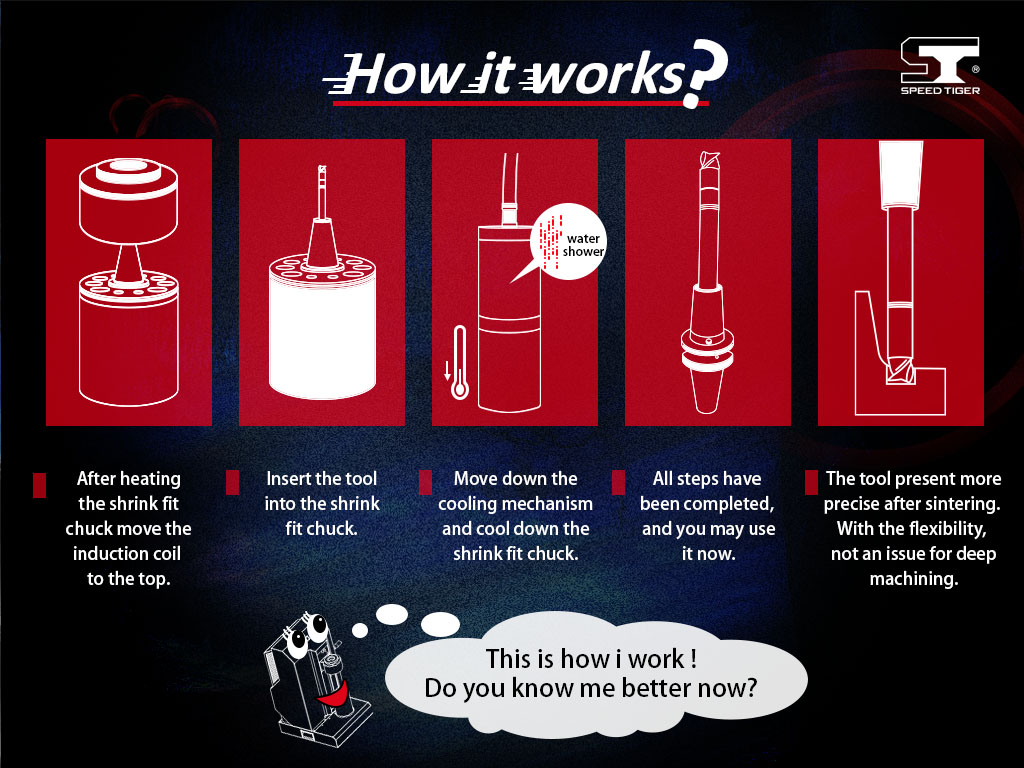

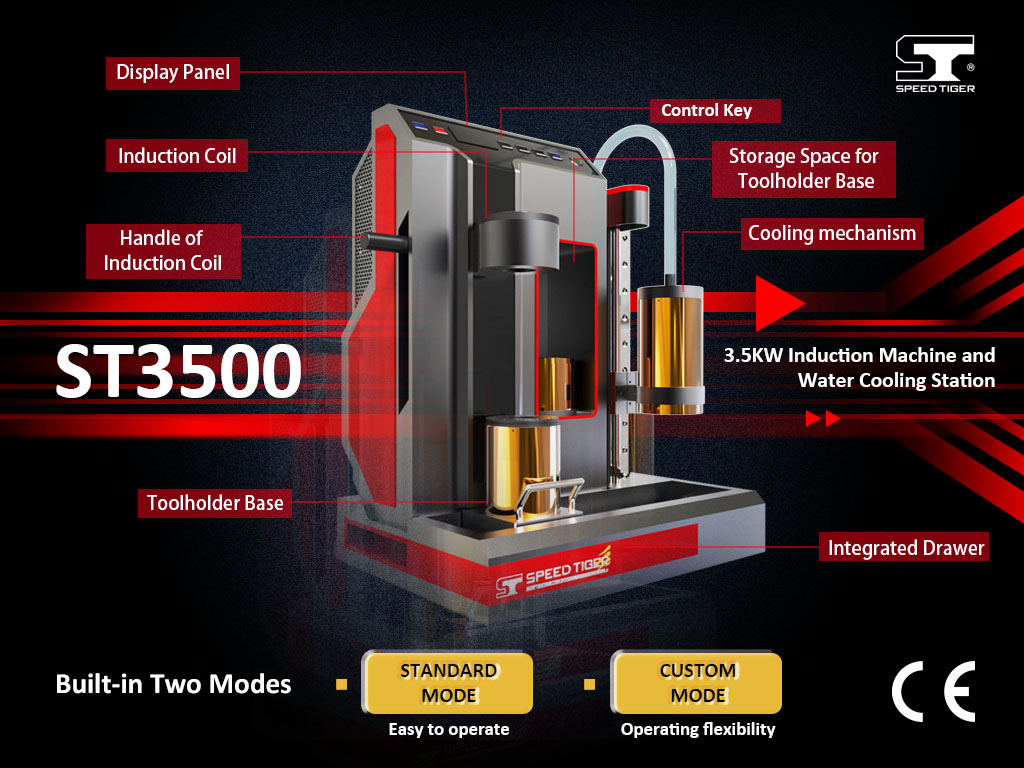

ST-3500 is an induction heating machine and water-cooling station with high precision, high efficiency, energy saving and environmental protection. According to the principle of thermal expansion and contraction, the tool and the tool holder are sintered seamlessly to obtain high-precision performance; also, by using low-powered heating can prolong holder life, and the unique integrated design of heating and cooling can save space. Based on the safety and convenience of use, the rail base design omits the need to move the holder after heating, thereby reducing the risk of burns to the user by the high-temperature holder. ST3500 uses circulating cooling design, using the water-soluble and non-toxic coolant liquid not only remove surface dirt but also rust-proof. Moreover, it can re-use for green processing.

The features of ST-3500:

ST-3500 cooperates with Speed Tiger Shrink Fit Chucks and Power Tips Series, will show the maximum performance and economic benefits of shrink system - 100% Solve the Problem of Processing Interference.

All you needs are the following 4 products:

You may say, Speed Tiger Shrink Fit System makes many choices and with more flexible applications.

Speed Tiger involved in business of design & manufacturing of solid carbide cutting tools solution since 1998. Specialize in producing high-performance Carbide End Mills, Drills, Turning Tools, Thread Mills, and Shrink Fit Machine.

Speed Tiger earned its leading position in the high-performance CNC tools market through actively communicating with metalworking manufacturers to develop milling tools that suit their needs. Our target is to create long lasting partnerships with high quality service and high performance carbide end mills.

MISSION -Be the supplier of cutting technology and the leader in the cutting field

VISION - Thrive to be the leading cutting tools manufacturer in Asia and assist enterprises in using high efficiency cutting tools to produce innovative and high quality products.

Advanced Production Facilities & Professional Coating Technology

SPEED TIGER introduced the latest technology in the production facilities, and have purchased more than 100 sets of grinding machines from Germany, Switzerland, Japan and Taiwan. We have been steadily increasing our production capacity to do mass production and customized tools in a short amount of time to keep up with constant requests.

We also introduced the coating technology and equipment from Switzerland in 2004, and became one of the pioneers in incorporating coating techniques with cutting tools. We are also specialized in developing coatings based on customers' requests.