Sophistication and precision are the dominant trends in the modern era, especially for products such as printed circuit boards and semiconductors. As a result, traditional computer numerical controls (CNC) machines are increasingly falling out of favor as such methods cause processed materials to warp from stress.

Sophistication and precision are the dominant trends in the modern era, especially for products such as printed circuit boards and semiconductors. As a result, traditional computer numerical controls (CNC) machines are increasingly falling out of favor as such methods cause processed materials to warp from stress.

NTS Technology Co., Ltd. specializes in the research, development and manufacturing of laser-based processing - especially in non-contact laser tools - and integration equipment. Such foundations allow NTS Technology to provide clients with the best applied laser solutions to process all kinds of materials for different industries.

Traditional laser processing works in two forms; in one, the laser source is stationary and processes the material on a mobile platform; in the other, the processed object remains immobile, while the laser galvanometer aims the laser point at different parts of the processed item.

The first method causes over-burn or uneven heat distribution when the platform speeds up or slows down, especially when creating patterns with corners. The second method suffers; from the small size of the focal lens, which constrains the laser’s material-processing area. For larger orders, this would require treating different parts and splicing the pieces together, which is labor-intensive.

To counteract such shortcomings, NTS Technology’s “on-the-fly processing” technology places the laser emitter on a platform guided by 4 adjoined axes, increasing the laser’s operating range to cover the entire work area. Combined with steady energy output, such designs also ensure precision, as the lens is positioned right over the desired location.

|

|

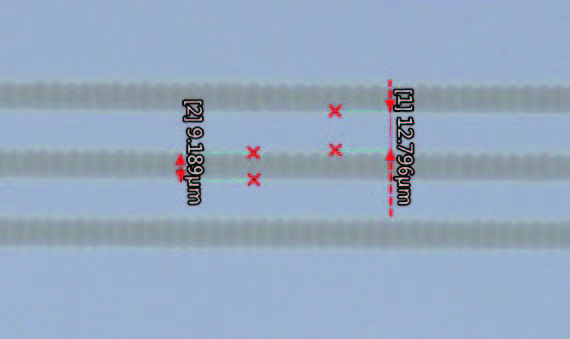

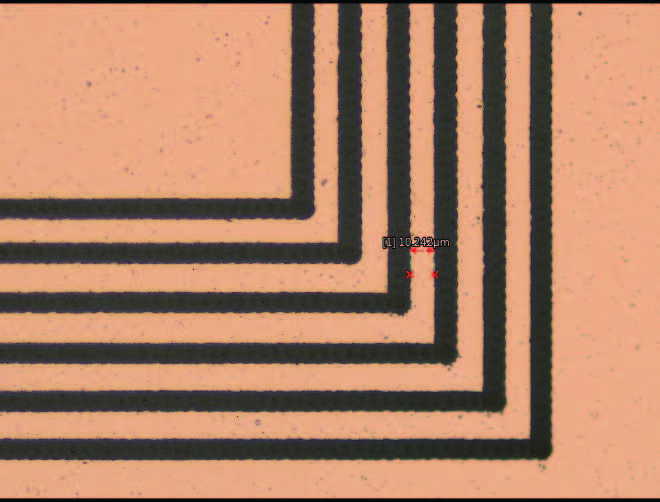

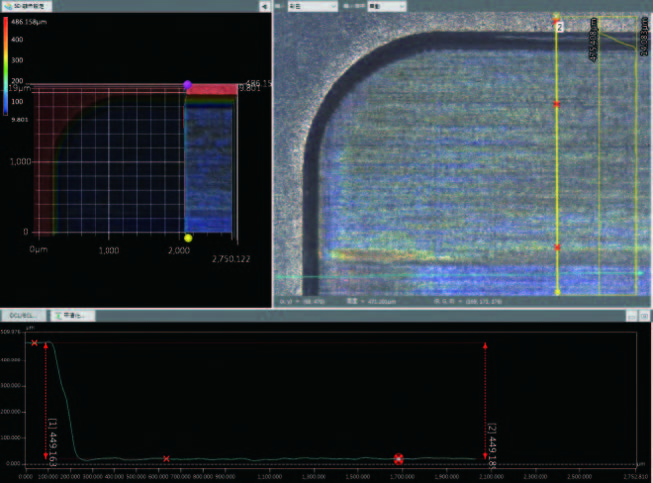

| Overall accuracy +- 5um , stitching error 0um. | Perfect Stitching error 0um. |

NTS Technology’s laser on-the-fly processing systems provides excellent accuracy with no stitching error, better quality, and improved efficiency at the same time.

NTS Technology General Manager Kim Chou said, “New technologies rarely see an increase across output precision, speed and quality; very often, an increase in precision or quality will see sacrifices of efficiency, and vice versa. Growth in all three sectors inevitably means that such technology is expensive.

“However, by offering integrative solutions that prize precision, quality and efficiency, NTS Technology knows how to hit the ‘sweet spot’ for different clients. NTS Technology could attract potential clients if the industry were more familiar with the advances its technology provides. Collaboration with potential clients would create applied uses for the technology, creating a win-win scenario.”

By providing Original Equipment Manufacturing (OEM) services, NTS Technology affords clients a taste of the advantages of laser on-the-fly processing system, paves the foundation for mutual collaboration, and provides NTS Technology with deeper insight into its clients and their products.

Using such insights, NTS Technology can suggest to clients which laser sources would be more appropriate for product processing and customize the laser performance curve for better efficiency or quality.

NTS Technology can also assist in planning automation solutions for effective production line and bring in more equipment to better prepare the client for the future.

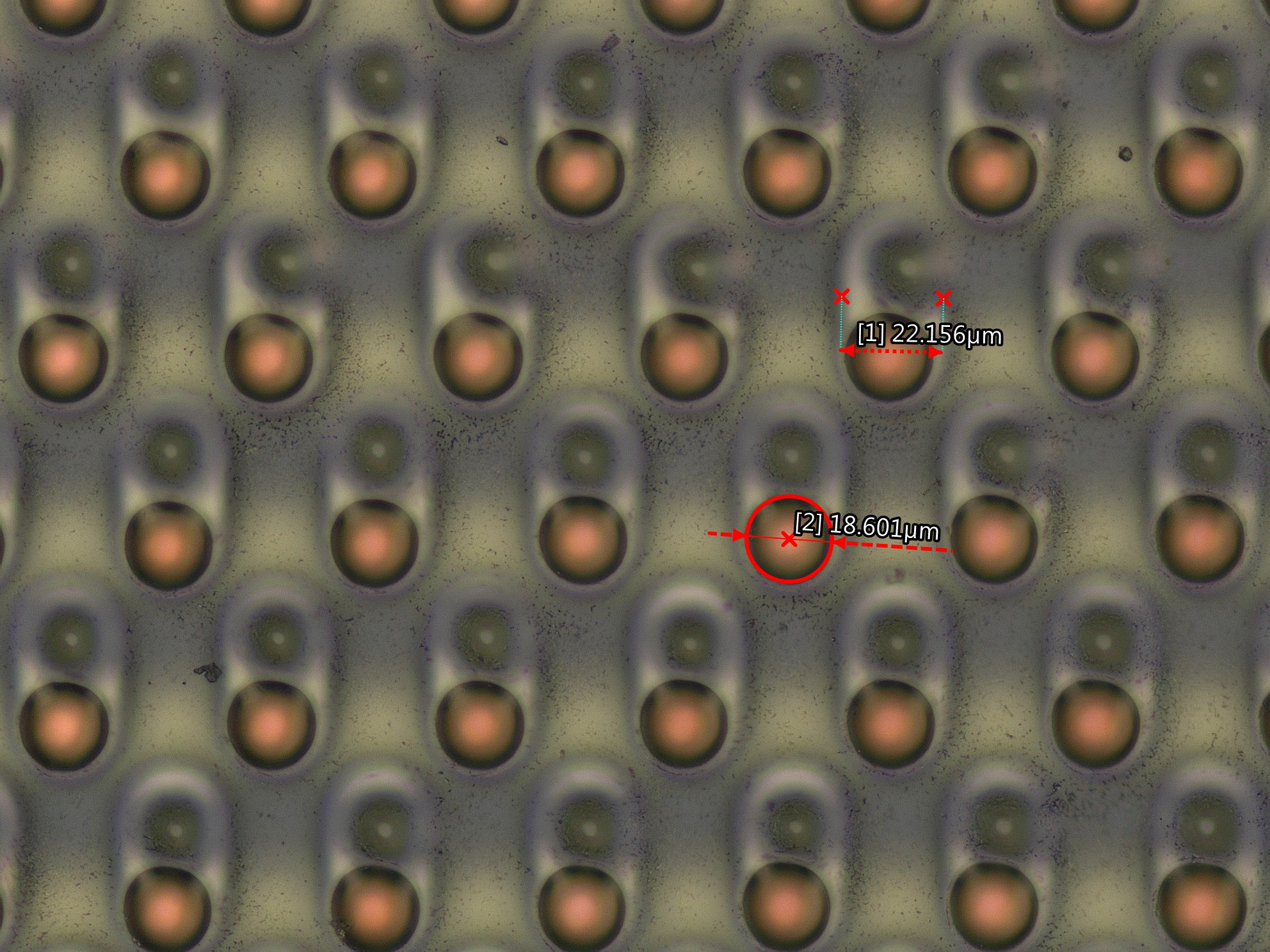

“Our customized services this year helped introduce laser-based processing procedures for an internationally renowned navigation hardware company. By providing them with products with greater precision, NTS Technology significantly improved their yield rates, increased throughput efficiency, and decreased overhead,” Chou said.

NTS Technology’s laser on-the-fly processing system is functionally comparable to similar products from other international brands, with the added incentives of having a lower price tag, better precision, and more flexibility.

While pricier than traditional laser-based processing equipment, NTS Technology’s products pay off by providing its clients with superb quality and efficiency, increased precision, and cutting down on steps, equipment and material loss.

According to NTS Technology, software is the key to how the laser on-the-fly processing system can simultaneously move both the platform and the focal lens and precisely aim the laser at any given point.

NTS Technology focused on software development to maximize product stability. Using the Time Partition Testing (TPT) methodology, NTS Technology mapped platform movements and calculated the compensation for each coordinate point, providing the hardware with precise controls.

|

|

| Better Efficiency via real-time coordination of motion and galvo. | Better Uniformity secured by non-stop processing. |

The software imports and changes drawing exchange format (DXF) files, assigning multiple functions to one key, providing control for all components and providing the best integrative experience possible.

“Our laser processing machines could be considered a closed-loop control system, allowing us to know, precisely, how far from the target the laser is at, giving us more control over the final products after processing,” Chou said.

Recognizing that the laser source is the most critical component of its machine, NTS Technology has long worked with primary laser source providers in Europe and the US. As a result, it can recommend the appropriate types of laser sources for its clients.

|

|

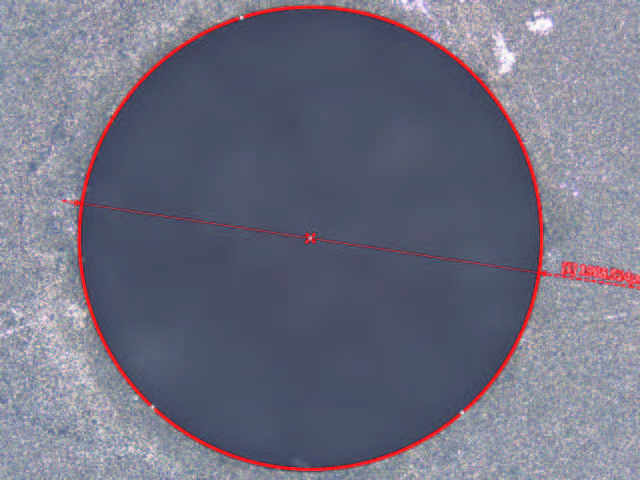

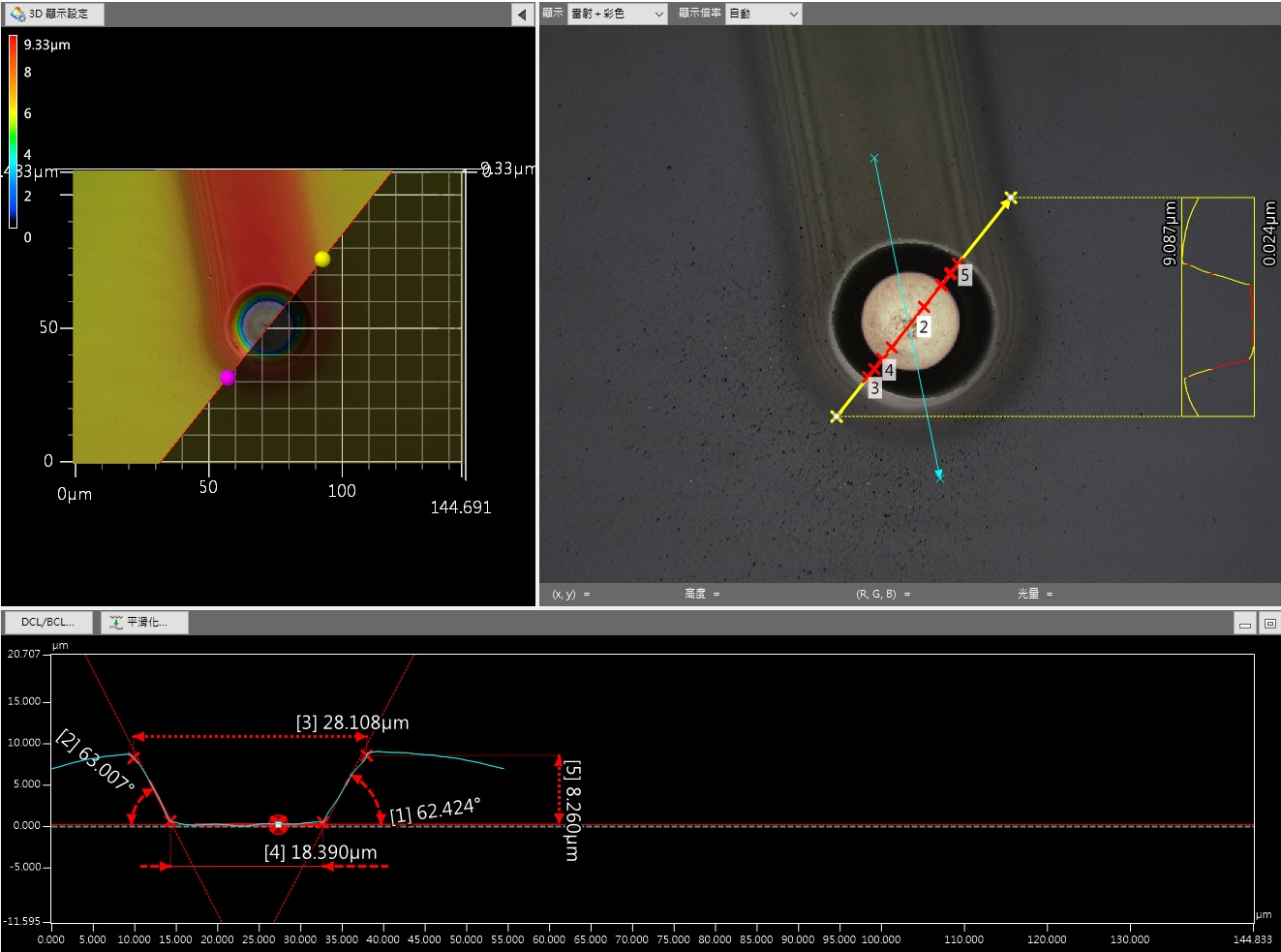

| Intergrated 4 Axes simultaneous machining could reach tolerance between ±2u | Laser control can easily achieve Blind Via Hole【BVH】drilling. |

The company assists with laser source customization to achieve the desired power output curve at working rep. rate. These services allow NTS Technology to help its clients achieve maximized production capability with enhanced quality of processed goods. The company also offers a complete line of after-sale services, including maintenance, training and equipment tuning.

NTS Technology’s laser on-the-fly processing system will be the go-to solution to broaden any company’s profit margins, especially as the industrial sector begins to embrace the third generation of semiconductor chips, the 5G network and ceramic applications.

About NTS Technology