As the industrial sector moves into a new era of automated manufacturing, pneumatically-powered components will become more diverse in function and see greater applied uses on various kinds of machinery.

Taiwan Chelic Co.Ltd., designating itself as a crucial supplementary manufacturer in the effort to achieve industrial automation, is prepared to utilize its 35 years of experience developing pneumatically-powered components to meet the challenges of the new era.

Out of all energy sources available to the industrial sector, pneumatic power has the lowest overhead, making it one of the most approachable clean energy sources. In recent years, the industrial sector has been trying various methods to utilize pneumatic energy to power a broad range of machinery.

In light of ever-advancing air pressure technology, industrial technology and material science, the company’s creation of new cylinders, grippers, vacuum pads and air source units to provide cleaner and more energy-efficient pneumatic-powered machinery for AI automation has never faltered.

Chelic is the first company in Taiwan to research and manufacture rodless cylinders and attendant guide rails. The machine was designed with a hardened frame to make it resistant to shock and could be used for special processing, such as operations in clean rooms.

Chelic’s rodless cylinder could be separated into mechanical cylinders, with better transmission and can work on more lengthy procedures than the magnetic dipole cylinders, which are quieter and quicker.

Compared with traditional pneumatic ones, the different pistoning motions of the rodless cylinders allow Chelic to build smaller frames.

A traditional pneumatic engine performing a stroke 350mm in length would require double the number of cylinders for the task and occupy around 800-850mm of space, while a rodless cylinder would only occupy an area of 380-400mm, the company said.

Chelic’s magnetic cylinders can perform a maximum stroke of 1,200mm, while its mechanical cylinders reach 1,400mm. Both mechanical and magnetic cylinders can be equipped with magnets and sensors for more precise control over piston movements, resulting in a spatially effective pneumatic pistoning solution.

Chelic provides a range of energy-efficient vacuum modularization solutions that are attuned to their clients’ needs, such as vacuum generators, silencers, manual or automatic vacuum drainage systems, shut-off valves, digital or analog pressure gauges, and others.

The company’s UFMLV 300 series Precision Filter Soft Start-Up Valve Module, for example, can reach a maximum flow rate of 7,000L/min, generate a vacuum environment, provide material filtration, and sense and detect anomalies while being energy-efficient.

In tandem with air combinator units, the start-up valve expedites inspections and maintenance procedures and protects the equipment and the workers.

Chelic understands that, at times, its clients may only require a part of the machine, and it has very flexible purchasing policies that allow clients to opt for specific details instead of the whole machine. For instance, clients can purchase the on/off switch and the vacuum generation and forgo any other equipment.

Such flexibility of purchase grants clients ease of installation by simply plugging in the air intake and turning on the machine.

With robotics in automated factories becoming ever more prevalent, Chelic is aware that robotic arms hold onto items primarily by clipping or using suction cups and fields such products for sale.

Chelic provides over 20 suction pads for clients, ranging from one-stage to two-stage, mark-free, anti-slid, flat, bellow-type and film-type pads. The company also offers micro vacuum pads only 0.7mm in diameter, providing the most appropriate vacuum pads for clients of different industries.

|

|

|

| PAM series Micro Vacuum Pad | EDQ series 3-Finger Electric Gripper | HDE series Comp act Plus 2-Finger Parallel Gripper |

Citing the food packaging industry as an example, the company said food packaging was usually light with irregular surfaces, making it difficult to latch onto using traditional hard suction pads. Instead, Chelic’s bellow-style, or micro vacuum pads, would resolve the issue.

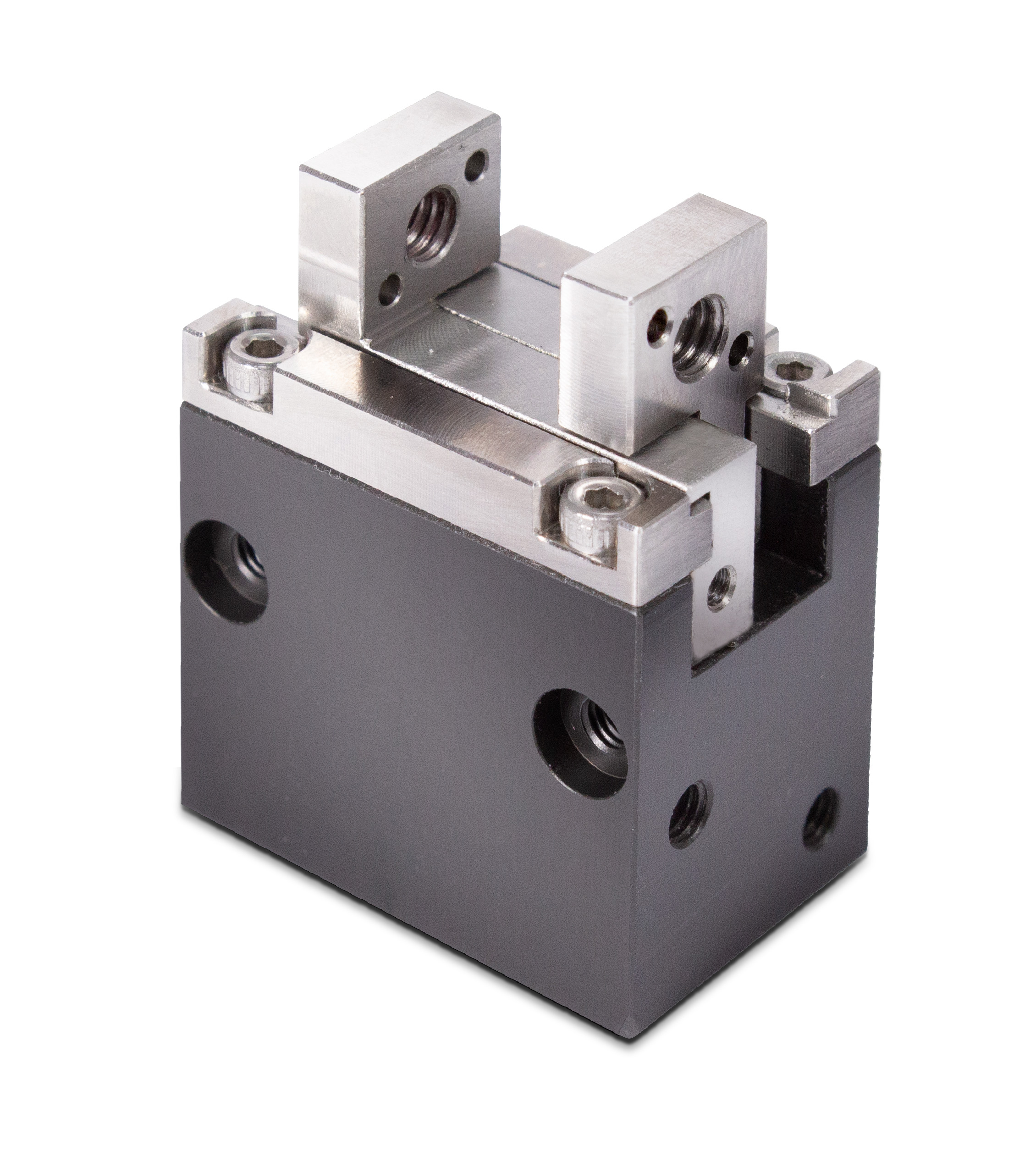

Chelic also offers parallel grippers, Y-shaped grippers and three-jaw grippers that are either pneumatically or electrically powered. In addition to standard product series like the HDP series, the company also includes guided-rail grippers, power grippers, and other gripper designs with operation in clean rooms in mind.

For example, according to the company, the HDE micro gripper series has a bore diameter of 8mm, which is 50 percent smaller than the standard HDP series.

During the COVID-19 pandemic, Chelic provided rapid support for face mask manufacturing and medical inspection equipment, allowing Taiwan and the world to become better equipped to deal with the pandemic outbreaks.

The company has won the Taiwan Excellence Award for at least seven consecutive years and is the owner of patents for over 80 products, among which 36 have been Chelic’s inventions.

However, the company is not resting on its laurels and plans to provide more electronically controlled products next year and increase the choices for automated machinery and equipment for existing and potential clients.

Chelic’s Pneumatic Components Energy-saving Intelligent R&D Center makes annual updates to existing products. In addition, it develops new products based on industry trends in Japan, Europe and the US to ensure its pneumatic components and automated equipment keep up with international trends.

In addition to providing critical components for automation, Chelic is willing to invest more to deliver technology and services to enable product customization for clients through new designs or making minute changes to standard products.

Chelic aims to help its clients realize their goals of transitioning their production lines from traditional industry to full automation.

About TAIWAN CHELIC CO., LTD.

TAIWAN CHELIC Youtube Channel

https://www.youtube.com/@chelic5750

Chelic(TAIEX:4555) is one of the market leaders specializing in pneumatic components which supplies to the global market. The product range is from primary type for general occasion, to high-end environment.

The innovations are released and awarded every year to correspond to Industry 4.0 trend.

Today, Chelic operates product development and manufacturing for eight ranges – FRL units, valves, actuators, vacuum equipment,electrical actuators, and so on. Furthermore, the pneumatic components distribution and technical supports through subsidiaries and overseas’ distributors.

By establishing an R&D center in Taipei, Taiwan, the company consistently demonstrates its capacity for innovations in new designs, which are continually honored with TAIWAN EXCELLENCE on a year-to-year basis.

Along with strict adherence in manufacturing and being detail-oriented, every employee looks for providing outstanding quality service.

Chelic prides itself in providing its customers and partners with products that are highly-efficient, energy-saving, and competitive in various industries.