Many manufacturing processes in the semiconductor or optoelectronics industry - such as the Equipment Front End Modules, the Standard Mechanical Interfaces and Stocker Systems - underscore the necessity of replacing human workers with automated machinery.

The Taiwan-based Sanwa Engineering Corp. was first an agent for foreign brands but later came into its own, manufacturing integrated customized equipment, designing circuit boards, mechatronic integration, software programs and machinery design.

Sanwa’s willingness to consider things from the client's perspective, including software and hardware design, the possible scenarios that clients would come across, and how the machinery can be used outside its intended role, helps make its price competitive.

In addition, its experience allows deliveries of complete solutions for its clients - from design to manufacturing - within four months, regardless of the number of products ordered.

Sanwa’s Chief Technology Officer, Eenie Chang, said, “A US client once asked us to do a job that involved removing wafers, clearing both sides, and returning the wafers to the equipment. The entire job was very detail-oriented, but after much discussion, we provided the client with a piece of equipment that can remove 25 wafers from the production line in one go, increasing the clients’ efficiency and yield rate.”

Sanwa recognizes that the semiconductor and panel industry operates on fast innovation cycles, and most manufacturing equipment has short operational lifetimes before they are replaced by succeeding generations of equipment.

The issue is further complicated because every semiconductor company has unique software and uses different protocols and programming languages, leading to more extended training and machine testing before workers can operate the machine.

“Many of our client's operations are not significant and hire relatively little staff, making it resource-intensive for them to keep a software design team on hand after purchasing the equipment.

Sanwa’s platform allows our clients to apply Sanwa equipment in the most optimized way without the need to invest in human resources for software design and maintenance,” Chang said.

Developing a software system and equipment with altered base-level firmware allows clients to allocate more waypoints for automated machines. In addition, the optimized user interface maximizes user experience and alleviates clients’ need to learn complex programming languages.

This is only possible by closely working with the client and having them provide their production plan cycles and the specifications of what other equipment they are using.

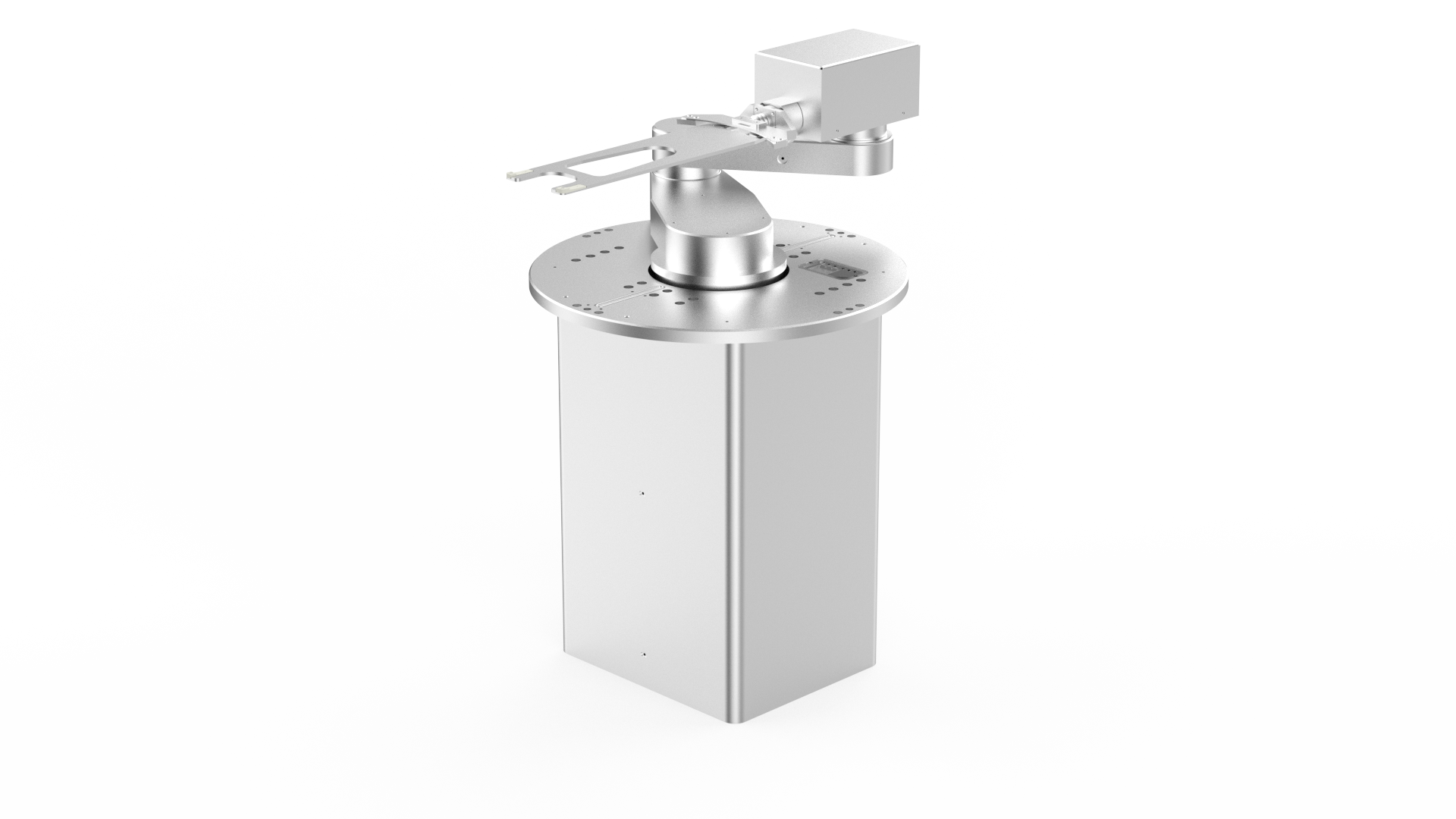

Sanwa’s solid foundations in robotic arms and other automated equipment for semiconductors and optoelectronic factories make it possible to provide clients with suggestions for multiple components and choices so that the final product best suits their needs.

The ballooning size of liquid crystal display (LCD) panels after the 5th generation required larger robots to process and manufacture. In addition, the panel’s increased weight also caused deviation of the fine metal masks within the panels.

Sanwa’s new line of robotic arms resolves the problem in which robotic arms could cause transport errors or create wear and tear on the product from lack of rigidity. The new system, which retracts and extends vertically, ensures that the arms picking up or setting down the LCD panels do not collide during transportation.

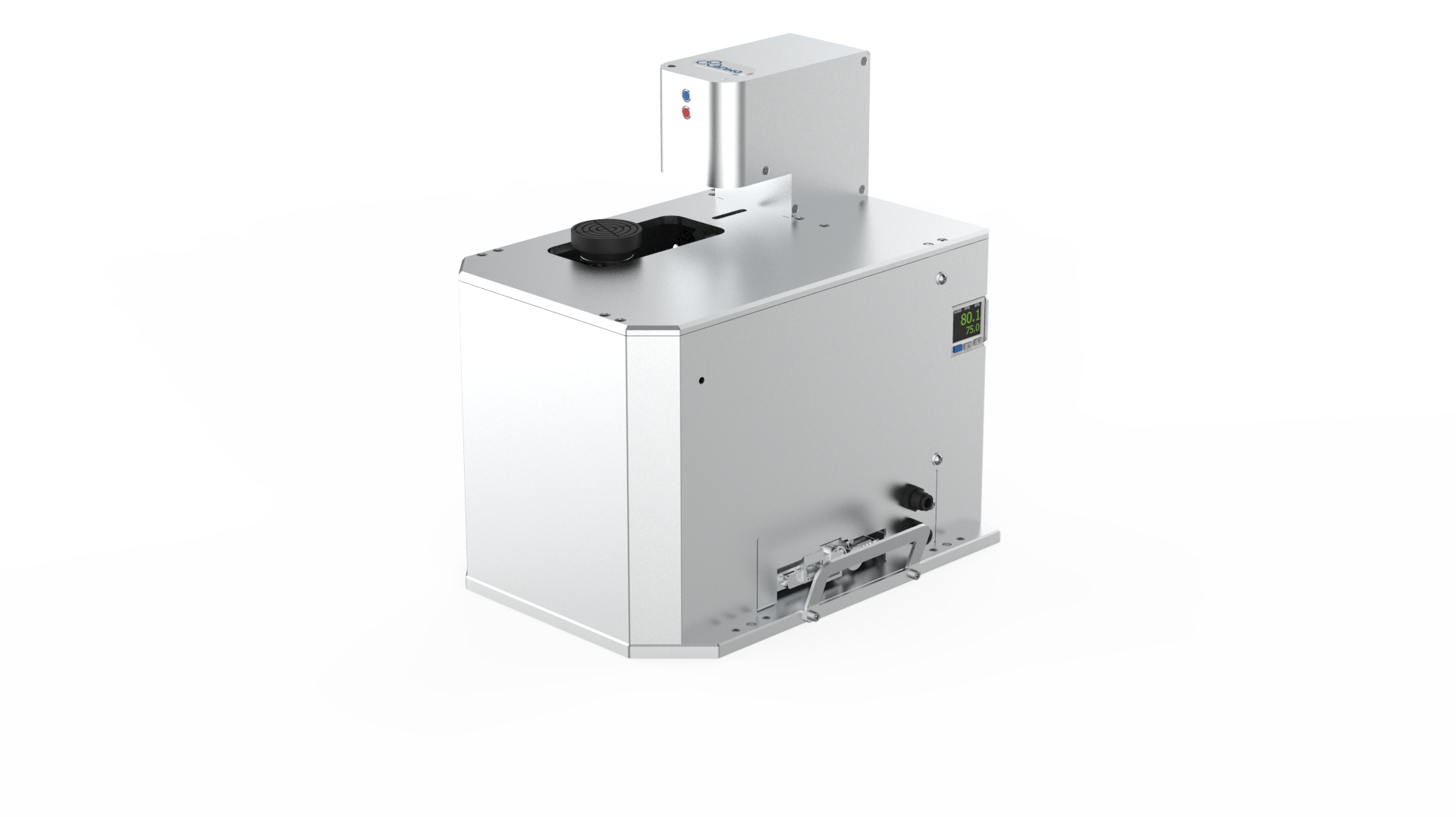

Mindful that its equipment will have to function in cleanrooms used to manufacture semiconductor wafers or optronic products, Sanwa is very selective of what materials to use for wire coating or the machine frame and what kinds of magnetic fluids to use. Sanwa also ensures that its machines can work in a dust-free environment and would not upset the pre-set temperature and humidity.

Sanwa’s SV series of robots is approved to work in vacuum-sealed environments and is also authorized to work in class-1 cleanrooms compliant with ISO 14644-1.

Sanwa’s efforts to provide the best service do not stop at developing new products but also pay great attention to after-market services.

Towards that end, Sanwa’s maintenance department relies on the experience of its seasoned engineers, as well as the creativity of the R&D department, to provide maintenance or convert specific machine models from known Japanese, European and American brands.

Sanwa’s Applied Maintenance Division director said that aging equipment often suffers from discontinued services, citing how the original Japanese manufacturer no longer produces the robotics for stocker system mask aligners made a decade ago.

Sanwa reached out to the original Japanese manufacturer and collaborated to create a new line of robotic products for the machine, providing clients with new options for maintenance while extending the equipment’s service life.

When performing maintenance on equipment from other brands, Sanwa replaces the basic level firmware with their own, allowing the machine to integrate communication protocols from the original manufactured equipment with Sanwa’s. This method dramatically lowers maintenance and training times, reduces malfunction, and reduces the difficulty of servicing equipment.

Sanwa believes that only through constant dialogue can the manufacturer and the client be in sync in understanding the client's needs and wants in pre-sale and after-market services. Only then can we provide them with a product that is easy to maintain, have a long service life, and has excellent performance.

Sanwa believes its services will allow the company and its clients to grow and mature through collaboration.

About Sanwa Engineering Corp.

Unfettered creativity and pushing the limits.

A group of Taiwanese experts devoted many years to researching technology that would help automate industrial processes created Sanwa Engineering in April 2005.

Using its Clean Robot technology and related products as its flagship products, as well as its excellent customer service, Sanwa looked to make a breakthrough into the market dominated by products using technologies from Europe, the US and Japan.

As the only brand mass-producing Clean Robots, Sanwa is confident that its core technologies will allow it to develop products that will be more accepted on the market and realize its dream of establishing an internationally recognized brand based in Taiwan.