As many countries are beginning to develop hyper-aged societies, the industrial sector is hailing the development of robotic arms as the go-to answer to address labor shortages.

Companies are replacing manual labor with automated robotics for highly-repetitive front-end production. Robotic arms are increasingly used in the pharmaceutical and food industries to reduce contamination and ensure product safety.

In addition, the rehabilitative medicine sector is also seeing increased use of robotic arms, as they can provide more varied motions that benefit patients undergoing rehabilitation.

However, traditional factories’ transition to Industry 4.0 “smart factories,” even with the aid of robotic arms, has reached a technological threshold - traditional factories lack the space to install robotic arms and their controller units.

Observing how industrial sectors formerly reliant on manual labor are turning to robotic arms and believing that future industrial equipment must be more precise and refined to introduce efficient automated production lines.

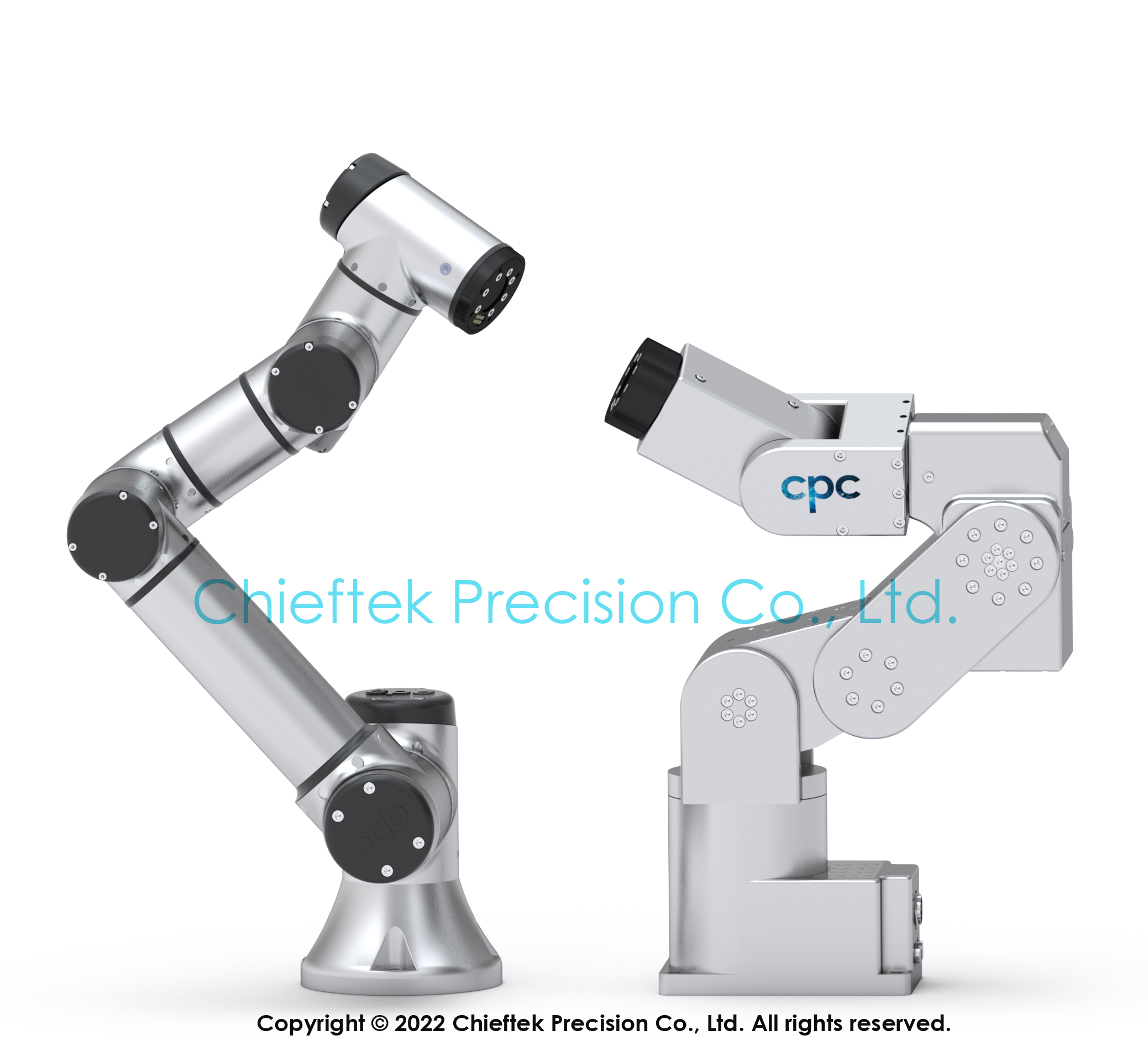

As a result, Chieftek developed the cpcRobot brand - including both the collaborative-use S0 6-axis robotic arm and the industrial-use DB0 6-axis robot arm - in 2021. Chieftek wished to provide clients with a higher price-performance ratio product addressing spatial issues faced by traditional factories transitioning to automated processes.

Micro robotic arms are small, making them a space-efficient solution for product lines. In addition, their software is compatible with industrial computers of different specifications, a further incentive to encourage factory owners to adopt the “smart factory” concept.

The S0 series, weighing only 3.5kg and designed to fit on one sheet of A4-sized paper when fully collapsed, can lift a maximum of 500g. In addition, the collapsible design grants the robotic arm a broader work parameter, and the designed alternative movement patterns allow the components to be flexible and agile without interference.

The S0 series products are also more precise, allowing factories to enact high-precision assembly operations.

Chieftek’s DB0 6-axis robot series industrial arms boast greater joint stiffness and weigh 4.7 kg while retaining repeatability precision within 5 micrometers (μm), making it an apt choice for applied uses with demands for high-precision capability.

The robotic arms, coupled with the TC-45-A-8 Automatic tool change system, can exchange multiple types of tool heads, maximizing the efficiency of one machine to suit numerous needs.

Chieftek is the only known company to have simultaneously developed both collaborative and industrial models of micro robotic arms and can mass-produce both production lines.

Chieftek self-manufactures vital components, such as motors, actuators, and encoders, guaranteeing a one-month delivery time when the order is accepted.

“We self-developed and installed a 23-bit high-resolution encoder in both the inner and outer robot arm joint control motors’ feedback systems to ensure maximum precision,” the company’s product manager Wu Hsuan-chun said.

Chieftek uses its own programmable logic controller (PLC), named “cpcStudio,” which conforms to the standard IEC 61131-3 programming language and includes multiple multi-function libraries.

Developing its own PLC allows clients more flexibility to meet demands, as opposed to other systems on the market that rely on prescription programming limited to a specific scope.

cpcStudio also supports industrial communication protocols, such as EtherCAT and Modbus TCP. In the future, cpcStudio will also utilize the OPC Unified Architecture (OPC UA) communication protocol to improve interoperability with third-party software.

It also allows the uploading of data to the Supervisory Control and Data Acquisition (SCADA) control system architecture, or the Manufacturing Execution Systems (MES), for Big Data analysis.

Chieftek’s past experiences developing miniature linear guides and direct drive motors allow the company to confidently say it produces the most precise and accurate micro robotic arms on the market.

About Chieftek(TAIEX:1597)