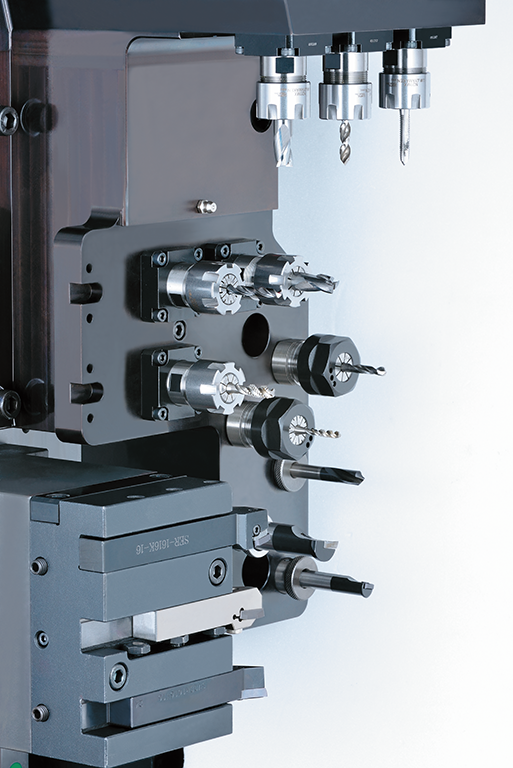

The trained engineer is often considered very difficult to manage nowadays. Thanks to the machine’s Mill-Turn function, it saves labor costs and reduces the number of machines from three down to one.

DY60 has been utilized in various industry sectors, including Automotive, Aerospace, Hydraulic, Medical, and also for electrical parts. There are several successful turn-key cases worldwide, especially in the European Union. MYLAS has shown that it fulfills high-quality standards.

MYLAS is also capable of customizing automation based on the customer’s workpiece. It analyzes the cycle time, rhythm, suitable machine, and of utmost importance, the total cost of the machine. In addition to this, the company designs automation such as 6 axes robot, gantry robot, or even vibration bin automation depending on the workpiece. MYLAS focuses on making machines which are suitable for their clients, and not over-design. The company takes into account the ROI, knowing it is of key importance to its customers.

DY-60 has embedded internet settings allowing for connectivity with different protocols. In 2017, MYLAS completed its first internet project equipping the DY-60 with a FANUC controller. The project uses the MT protocol for connection. However, more and more customers are no longer satisfied with standardized frameworks. Thus, MYLAS is developing new APPs on the controller and smart machine functions so that customers can employ them in a closer and more practical way. This is expected to be ready in 2023.

MYLAS endeavors to make machines that are powerful, with more functions, and affordable prices for their clients.

|

|

|

| Bicycle Parts Material :Rods / Aluminum Cycle Time : 3 Minutes |

Car Parts Material: Square Rods / Stainless Steel Cycle Time : 5 Minutes |

About MYLAS

https://www.mylascnc.com/

MYLAS was established in 1985. Headquartered in Taichung, the company started from the Auto Lathe Series which has sold more than 65thousand machines worldwide. In 1999, the Jiangsu branch was established to target the market in China. In order to satisfy the skyrocketing demand, the Shengang branch was founded in 2004. More and more complex machining inquiries had been sent from customers which pushed MYLAS to further make progresses to the function of their CNC turning machines. The company offers simple lathe, dual spindles, double turret types, and three channels design machines.

Mylas has grown to value two main things as a family company. On one hand, loyalty, and support. Continuity and relevance is the other. It would be fair to say that Mylas has followed a path not unlike many others in the CNC industry. Building and consolidating its strength on the back of sturdy machines and solid engineering. The company believes that their strength is starting to shine through as they come up with new ideas and map out their path for the future with a renewed commitment to their customers.