Li Ming Machinery Co. Ltd, an established name in the reduction drive manufacturing industry for the past 50 years, is leading the development of more sensitive reduction drives allowing broader applications of the device to other products.

The reduction drive is an integral mechanical component used in manufacturing equipment for screen panels, chips, and other smart-manufacturing equipment, such as robotic arms and automated guided vehicles (AGVs). Due to its crucial role, increasing the controllability of reduction drives opens more doors for reduction drive applicability in production hardware or intelligent technological products.

Li Ming specializes in the research and development (R&D), planning, and production of reduction drives of all kinds, and over the past five decades, it has provided its clients with the best reduction drive on the market.

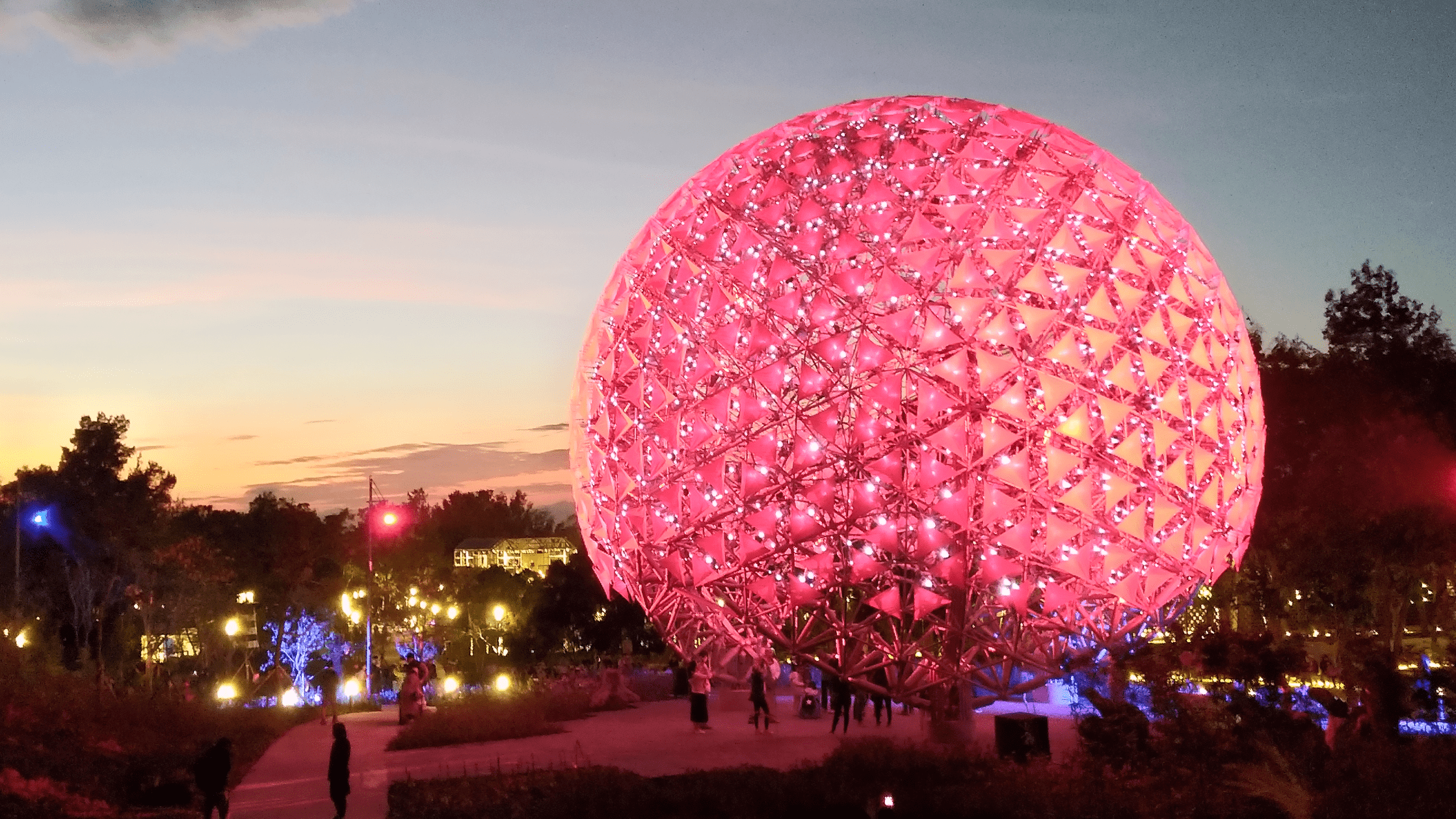

During the 2019 International Flower Expo held in Taichung, Li Ming relied on its professional knowledge of machinery and, in just under two months, designed, developed, manufactured, and assembled the largest flower-themed installation art using 700 planetary reduction drives.

Like other companies leading in their respective fields, Li Ming is aware of the Industry 4.0 trend. As the concept becomes more prevalent, newer devices, such as the harmonic and RV reduction drives, must meet the high precision and rigidity demanded by reduction drivers in automated production equipment, robots, robotic arms, and self-driving vehicles.

“The more a factory is automated, the more reduction drives it requires, and different demands from different types of factories are driving the need for varying reduction drives,” Li Ming General Manager Using Lin (林育興) said.

In addition, Li Ming is also exploring industrial robot optimization. For example, Li Ming’s introduction of a modular reduction drive on the fifth and sixth axes of the six-axis robotic arm product integrating two transmission components significantly decreases robot size and increases efficiency.

Anticipating growing demand for higher-end products, the company had, over the past decade, established an entire production line, ranging from the R&D department to a gears heat treatment plant.

In addition to establishing the production line, Li Ming is also purchasing more advanced machinery from Europe and Japan to maintain its production capacity and edge in the reduction drive production industry.

Lin said that while the technology behind harmonic and RV reduction drives fundamentally differs from the standard device, they still share 70 percent similarity with the expected reduction drive.

“This means that the company would only have to devote 30 percent of R&D efforts to develop cutting-edge harmonic and RV reduction drives,” Lin said.

Li Ming has also implemented multiple robotic arms and other equipment for automated production, all using Li Ming’s self-produced and reduction drives, to help its factories transition to Industry 4.0 automated factories.

Five years ago, Li Ming self-developed and produced multiple RV and harmonic reduction drives. Both products quickly entered mass production, as Li Ming’s extensive experience and production capability guaranteed the products’ quality.

Liming ROBONICDRIVE Harmonic Reducer Strain wave gearing sets

Liming CYKODRIVE Cycloidal RV gear set

Li Ming’s products quickly cornered a place on the market through established channels.

By upgrading its factory with self-manufactured products, Li Ming ensures that it has the know-how and capability to remain at the front of the line and produce better, quieter gears that see more sustained use and greater applicability.

Lin said its longest-serving harmonic reduction drive had been online for over two years, or more than 20,000 hours, serving far longer than the harmonic reduction drive produced by major Japanese plants.

Quantitative data obtained through non-stop practical trials shows that Li Ming can produce reduction drives that are as good - quieter, with equal precision, long service life, and excellent efficiency - as other world-class brands.

In addition, Li Ming is the only Taiwanese company capable of producing hypoid-gear reduction drives. The hypoid-gear drives have a higher reduction ratio over the traditional worm gear and worm wheels, making them a preferred choice for AGV manufacturers.

Li Ming has kept up with technological advancements throughout the years and kept production lines of older models running, making them the only provider to have all categories of reduction drives used in the industrial sector, regardless of era.

“You won’t find a second company in the world that boasts the same,” Lin said.

Li Ming is committed to developing reduction drives and will continue to be the most stalwart and reliable provider supporting industrial technology needs.

LI-MING Machinery Co., Ltd. is a specialist in design, manufacturing of a wide range of high-tech speed reduction motor and helical gear reducers, worm gear reducers and planetary gear reducers. In recent years, to meet customers' requirements of quality and price, it has dedicated itself to constantly upgrading the performance of gear reducers, maximizing efficiency, and providing the most comprehensive technical support.

LI-MING designs and manufactures: Helical Gear Reducers, Bevel Gear Reducers, Worm Reducers, Planetary Reducers, Cycloid Gear (RV) Reducers, Harmonic Reducers, Hypoid Gear Reducers, & Customized Reducers.

LI-MING’s team background is in the field of high-tech. Under the company's policy of "Quality Priority; Customer Satisfaction" and "Intelligence; Sincerity; Honesty", the company’s enterprise culture is based on practicality, constantly learning advanced management systems and commitment to excellence.