Specifications:

Travel X/Y/Z (mm): 700 / 500 / 515

Travel A/C (Degree): +30∘~120∘ / 360∘ (continuous)

Table size: ψ410 mm

Max. workpiece size: ψ500 x 300 mm

Table load capacity: 200 kg

ATC Magazine positions: 30 (std.) / 48 (opt.) / 60(opt.)

FANUC / SIEMENS / HEIDENHAIN Control available

UX500 five-aixs M/C is developed with a modulize concept as a solution for high labor cost and technician shortage issues in European and American markets. It has the high efficiency, labor-saving, mixed prodution line suitable, and expandable features.

Single unit machine with high rigidity, accuracy, and efficiency features offers ease of operation and a relatively compact footprint.

Application:

• Automobile: control arm, bracket, engine block.

• Aerospace: blisk, impeller, turbine blade.

• Medical: titanium artificial knee joint, dental part.

• Mold & die: tire mold & die in tool steel, plastic mold.

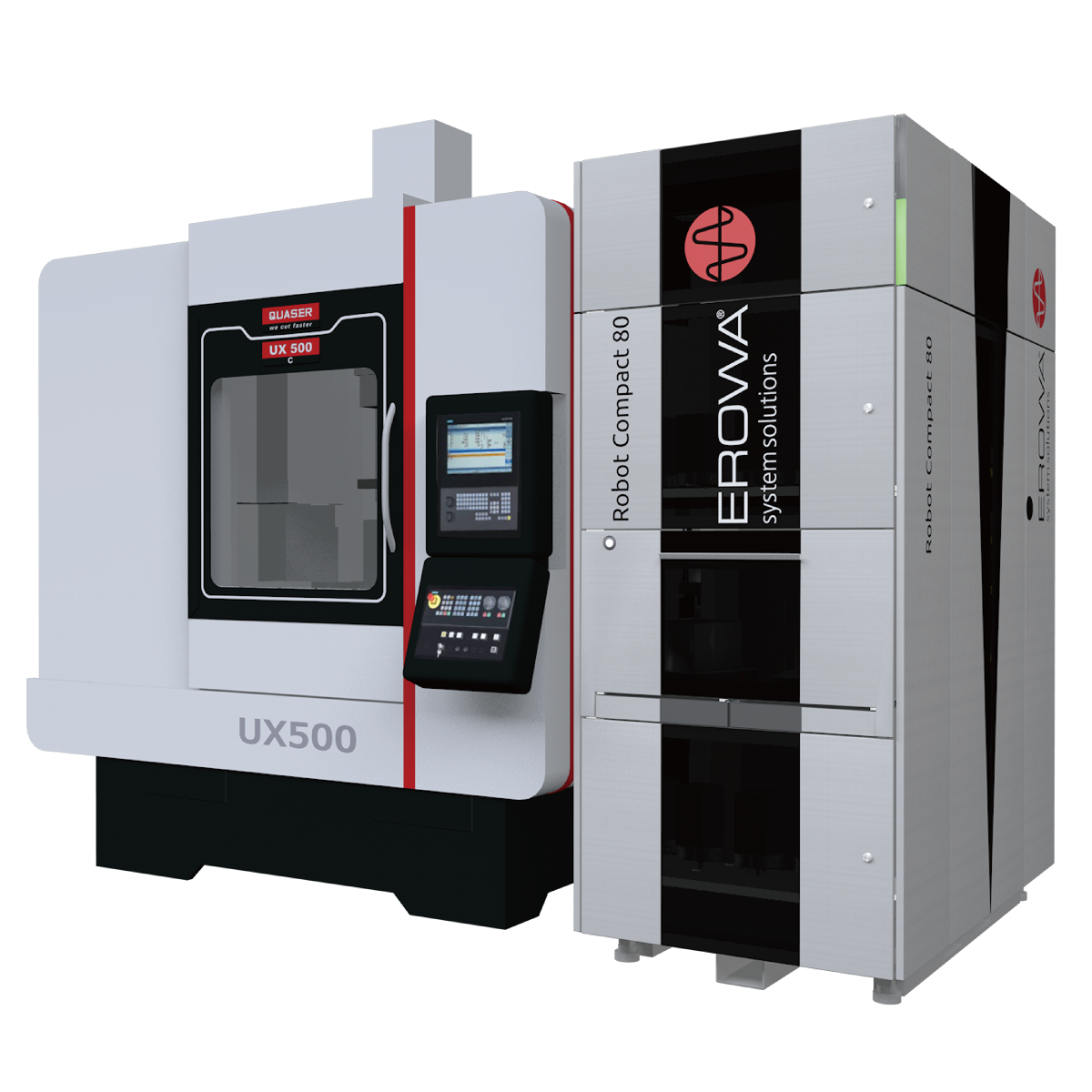

UX500 with Erowa Automation is a versatile five-axis VMC with automatic workpiece changer. End users can easily expand the number of work pieces to the machining demand to maximize the job profit.

QUASER MACHINE TOOLS, INC. was established by Mr. Edward Shar and Mr. Samuel Shieh in 1991. The company name is based on fundamental principles for success in the machine tool industry - QUALITY, SERVICE (QUA SER) and continuous DESIGN INNOVATION. Startin Hsieh, CEO of QUASER Group, upholds these principles. He expanded the company into an international group, and actively promotes innovation in order to achieve responsible manufacturing and to provide customers with a comprehensive range of competitive solutions.

The company has a wide range of vertical, horizontal, 5-axis and mill turn machining centers. These product lines can be combined with full automation equipment such as pallet changers, full FMS cells and robotic technology. The Quaser UX-500 Five-Axis Machining Center with Erowa Automation is its latest bridged structure five-axis machining center. It was developed with a modularized concept as a solution for high-labor cost and technician shortage issues in European and American markets. It has high-efficiency, labor saving, mixed prodution line, and expandable features. Single unit machine with high rigidity, accuracy, and efficiency features offers ease of operation and a relatively compact footprint. Its applications include automobile, aerospace, medical, mold & die. The UX500 is a versatile five-axis VMC with automatic workpiece changer. End users can easily expand the number of work pieces to the machining demand to maximize job profit.

QUASER is the partner of choice for many well-known machine tool builders in Japan, Germany and the UK, with a reputation for speed, accuracy and precision. The company’s vision is to become a top player in industrial application solutions worldwide by providing high-precision quality platform to integrate high tech application into systems such as Laser, EDM, high-speed milling, turning and grinding. QUASER proposes industry-leading and comprehensive solutions by providing value-added product service to help its customers become more productive and efficient.